| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

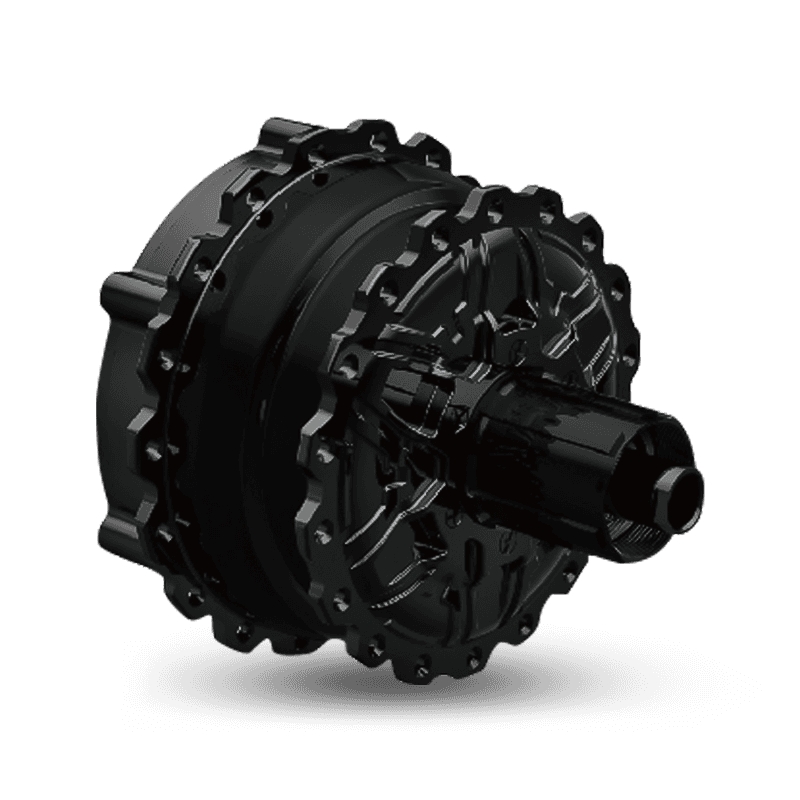

High Performance E-Kart Motors

-- Steady & Reliable Manufacturer --

Engineering Speed: The Professional E-Kart Solution

The transition from gas-powered karts to electric systems has fundamentally changed the sport of karting, offering instantaneous torque that combustion engines simply cannot match. Our high performance E-kart motors are engineered for the extreme thermal and mechanical stresses of the racetrack. Leveraging 30 years of electromechanical innovation, we have developed a series of motors that prioritize power density and heat dissipation—the two most critical factors in maintaining top speed across a 15-minute racing heat. Our 5,000sqm manufacturing facility is equipped with specialized test benches that simulate high-speed racing cycles to ensure every motor can handle the "redline" performance demanded by competitive drivers.

In the world of E-karting, weight is the enemy of acceleration. By utilizing advanced aluminum-magnesium alloys for our motor housings, we have achieved an industry-leading power-to-weight ratio. These housings are produced using our in-house 500-ton die-casting machines, ensuring a pore-free, structurally rigid enclosure that can withstand the intense vibrations and G-forces of sharp cornering. This precision manufacturing extends to the rotor and stator assembly, where we use high-grade silicon steel laminations and oxygen-free copper windings to minimize eddy current losses and maximize electromagnetic efficiency.

The "HENTACH" spirit is about proving durability through action. While these motors are designed for speed, they are built with the same longevity principles that allowed our earlier designs to exceed 50,000 miles in field testing. For track owners and kart manufacturers, this translates to lower maintenance costs and higher fleet uptime. Whether you are building rental karts for a commercial facility or professional-grade racing machines, our motors provide the consistent, high-torque output needed to dominate the track. We combine mature management practices with cutting-edge manufacturing to deliver a racing solution that is both explosive in performance and reliable in construction.

Racing Performance Specifications

| Metric | Professional Series Value | Description |

|---|---|---|

| Peak Power Output | 10kW - 15kW | Short-burst acceleration power |

| Nominal Voltage | 48V / 60V / 72V / 96V | High-voltage racing compatibility |

| Maximum RPM | Up to 8000 RPM | Optimized for high-speed tracks |

| Torque Density | 4.5 Nm/kg | High torque in a compact frame |

| Cooling System | High-Flow Forced Air / Liquid Cooling | Integrated thermal management |

| Encoder Resolution | 1024 / 2500 PPR | Precise throttle and speed control |

| Vibration Resistance | Grade A (Industrial standard) | Resistant to high G-forces |

| Duty Cycle | S2-30min / S3-25% | Designed for racing heat cycles |

| Shaft Material | High-Tensile Alloy Steel | Resistant to sudden torque loads |

| Efficiency | 92% at rated speed | Maximizes track time per charge |

Racing and Recreational Applications

Our high-performance drive units are the heart of the modern racing facility. They are specifically designed for Professional Indoor E-Kart Centers where acceleration and rapid braking are constant. The motor's responsiveness allows for precise overtaking and a more engaging experience for the driver. Additionally, they are used in Outdoor Competition Karts where high top speeds and sustained power are necessary to handle long straights and varying track temperatures.

- Commercial Rental Kart Fleets seeking durable, low-maintenance power.

- Junior Racing Programs requiring tunable speed and power limits.

- DIY Karting Enthusiasts and custom vehicle builds.

- Autonomous Karting Research Platforms for university labs.

- Professional Karting Circuits for national-level competitions.

Competitive Edge in Thermal Management

The standout advantage of our E-kart motors is our proprietary Thermal Transfer Technology. Heat is the primary cause of power fade in electric racing. Our motor housings are designed with multi-finned surfaces and optimized internal airflow to pull heat away from the windings as quickly as possible. For high-end models, we offer liquid-cooled jackets that keep the motor at optimal operating temperatures even during back-to-back racing sessions. This ensures that the driver has the same level of power on the last lap as they did on the first.

Moreover, our motors feature high-precision sensors that provide real-time data to the controller, allowing for intelligent thermal throttling and over-current protection. This "smart" motor design protects the client's investment and prevents catastrophic failures during high-stakes competition. By leveraging our 30+ years of electromechanical innovation and ISO 9001 certified quality control, we provide a racing motor that outlasts and outperforms the competition, backed by a manufacturer that understands the nuances of precision processing.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China High Performance E-Kart Motors Manufacturers and China High Performance E-Kart Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体