| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

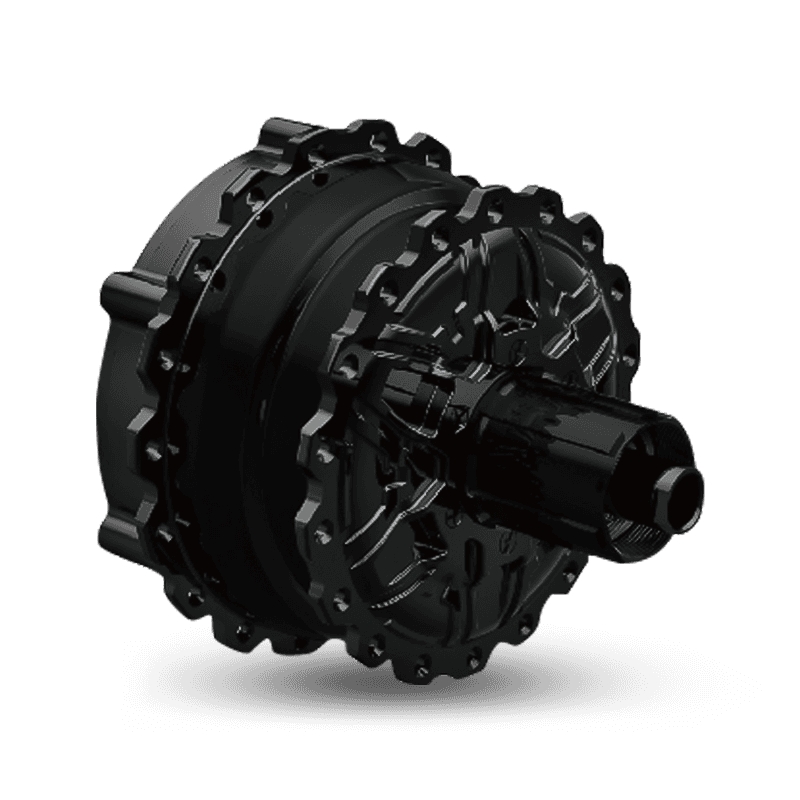

E-Cargo Bike High-Torque Hub Motors

-- Steady & Reliable Manufacturer --

Introduction to High-Torque Cargo Motors

The Electric Cargo Bike (E-Cargo Bike) is rapidly emerging as a critical player in the urban transportation landscape, particularly in scenarios demanding the efficient and eco-friendly transport of goods or family members. The core technology that enables these heavy-duty electric bicycles to achieve their impressive payload capacity and hill-climbing performance is the High-Torque Hub Motor.

What is a High-Torque Hub Motor?

A Hub Motor is an electric motor that is directly integrated into the center of the bicycle's wheel hub. This design combines the power output and the drive mechanism, eliminating the need for traditional chain or belt drives, resulting in a compact, low-maintenance structure.

For E-Cargo Bikes, standard bicycle motors often lack the power and torque required to meet their specific demands:

-

High Payload: E-Cargo Bikes are engineered to carry significantly more weight than standard e-bikes, with typical design payloads ranging from 100 kg up to 250 kg, encompassing the weight of the vehicle, the cargo, and the rider.

-

Frequent Stops and Starts: In urban delivery scenarios, the vehicle must frequently accelerate from a standstill. High torque is paramount during this initial startup phase.

-

Steep Grade Challenges: Even when fully loaded, the vehicle needs the capability to easily handle city slopes, bridges, or the ramps of underground parking garages.

The High-Torque Hub Motor is specifically optimized to address these challenges. Compared to standard hub motors, their design goal is to maximize torque output, providing substantial driving force even at low speeds. Torque is the physical measure of rotational force. For a loaded vehicle, it is more crucial than pure peak power, as it directly correlates with acceleration, smooth starts under load, and hill-climbing ability.

Key Technical Features of High-Torque Hub Motors

The superior performance of high-torque hub motors is primarily attributed to several key design and engineering characteristics:

1. Geared vs. Direct Drive Optimization

Most high-performance E-Cargo Bike hub motors utilize geared hub motors, which incorporate a planetary gear reduction system.

-

Geared Hub Motors: These motors include an internal planetary gear set that allows the motor to spin at a higher RPM with lower current. The gear reduction ratio then translates this high speed into the low speed and high torque required at the wheel. This not only provides powerful starting and climbing ability but also helps improve motor efficiency and reduce weight. When the motor is not powered, the gear system disengages, allowing for zero-resistance coasting.

-

Direct Drive Hub Motors: These have a simpler, gearless structure. Their torque is directly related to the size and strength of the motor magnets and windings. While highly reliable, they are generally less efficient and create magnetic resistance (drag) when coasting unpowered. In the E-Cargo Bike sector, geared motors are the preferred choice for maximizing torque and efficiency.

2. Winding and Magnet Optimization

High-torque motors employ designs with a higher number of pole pairs and a denser coil winding. This allows the motor to generate greater electromagnetic force for a given current input, thereby increasing torque output. Furthermore, the use of high-quality rare-earth permanent magnets (like Neodymium) ensures a powerful magnetic field, which is the physical basis for generating high torque.

3. Superior Thermal Management

Under heavy load and climbing conditions, the motor operates at high stress for extended periods, leading to heat build-up. Overheating not only degrades performance but can also permanently damage magnets and coils. Therefore, high-torque E-Cargo Bike hub motors often feature optimized casing designs (e.g., cooling fins) and internal structures to ensure effective heat dissipation, maintaining stable performance and longevity.

4. Robust Construction and Bearings

Given the bumps and heavy loads frequently endured by E-Cargo Bikes, the motor's bearings, axle, and casing must be designed with reinforced materials and engineering to withstand higher radial and axial stresses, ensuring reliability over long-term, high-intensity use.

Hub vs. Mid-Drive Motors: Why Hub Motors Remain Essential for E-Cargo Bikes

In the general e-bike market, Mid-Drive Motors are popular for their efficient use of the bike's gear system and natural riding feel. However, high-torque hub motors retain distinct advantages in E-Cargo Bike applications:

| Feature | High-Torque Hub Motor | Mid-Drive Motor |

| Torque Delivery | Direct and powerful, ideal for starts and heavy loads. | Delivered through the chain/cassette system, which can cause component wear. |

| Load Resilience | Power is applied directly to the wheel, independent of the bicycle gears. | High torque significantly accelerates the wear of the chain, cassette, and chainring. |

| Transmission Simplicity | Simplifies vehicle design; allows use of highly reliable single-speed or internal gear hubs. | Must utilize external or internal gear systems. |

| Maintenance Cost | Extremely low maintenance; almost entirely maintenance-free; tire changes slightly more complex. | High maintenance costs due to rapid wear of drivetrain components (chain, cassette). |

| Rear Wheel Drive | Ideal for rear-wheel mounting; direct thrust enhances vehicle stability under load. | Power is centralized at the bottom bracket for a lower center of gravity. |

Especially in commercial cargo applications, the minimal maintenance requirements and low wear on the drivetrain make the hub motor an ideal choice for logistics companies focused on high reliability and low operational costs.

Specifications

| Parameter | Detail |

|---|---|

| Rated Power Range | 250W - 750W (EU/US Compliant) |

| Peak Torque Output | ≥ 85 N.m |

| Gear Type | Patented Plastic-Steel Composite |

| Dropout Size (Axle) | 135mm / 145mm (Optional) |

| Weight (Typical) | 3.8 kg - 4.5 kg |

| Brake Compatibility | Disc Brake & V Brake |

| IP Rating | IP65 (Dust and Water Resistant) |

Specifications

| Parameter | Detail |

|---|---|

| Rated Power Range | 250W - 750W (EU/US Compliant) |

| Peak Torque Output | ≥ 85 N.m |

| Gear Type | Patented Plastic-Steel Composite |

| Dropout Size (Axle) | 135mm / 145mm (Optional) |

| Weight (Typical) | 3.8 kg - 4.5 kg |

| Brake Compatibility | Disc Brake & V Brake |

| IP Rating | IP65 (Dust and Water Resistant) |

Applications

-

Commercial Last-Mile Delivery: Ideal for courier services transporting packages in dense urban areas.

-

Heavy-Duty Utility Transport: Used by facility maintenance, mobile services, and industrial campuses.

-

Family Cargo & School Run Bikes: Reliable power for carrying children and significant weekly shopping loads.

-

Waste Management & Recycling: Low-speed, high-torque needs for specialized municipal applications.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China E-Cargo Bike High-Torque Hub Motors Manufacturers and China E-Cargo Bike High-Torque Hub Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体