| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

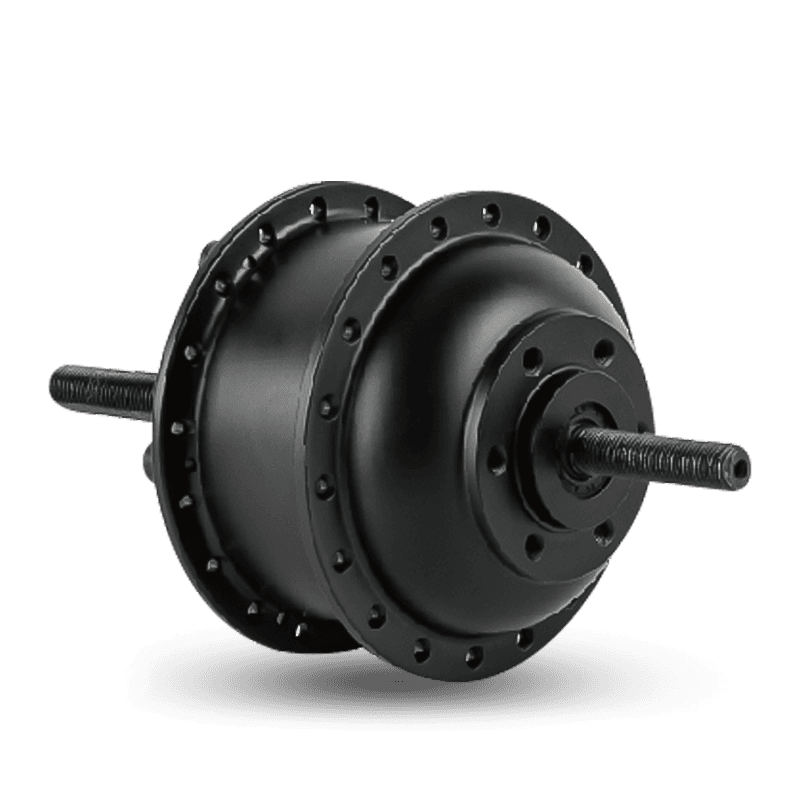

High Efficiency Hub Motors (85%+)

-- Steady & Reliable Manufacturer --

Maximizing Range: High Efficiency Hub Motors (85%+)

In the electric vehicle market, efficiency is paramount, directly translating into maximum driving range, reduced battery size requirements, and lower operating temperatures. Our High Efficiency Hub Motors are meticulously engineered to achieve a power conversion efficiency of 85% and often exceed 90% across the motor's most frequently used operational band (the cruising speed range). This benchmark is achieved through optimized electromagnetic design, high-grade material selection, and precision manufacturing that minimizes all forms of energy loss—electrical (copper losses), magnetic (iron losses), and mechanical (friction losses).

The primary driver of this high efficiency is the combination of a low-resistance copper winding and the use of high-grade Silicon Steel (electrical steel) for the stator laminations. We use ultra-thin laminations with minimal core loss properties, which drastically reduces the energy wasted as heat through magnetic reversal (hysteresis and eddy currents). This focus on minimal iron losses ensures the motor maintains high efficiency not just at its peak power point, but across the entire speed and torque curve relevant to real-world driving conditions, unlike many competitors who only quote a single, often irrelevant, peak efficiency figure.

Minimizing Losses Through Precision

Mechanical losses are minimized through two critical measures: Precision CNC Machining and the use of premium bearing systems. Our high-accuracy CNC ensures the air gap between the stator and rotor is uniform and optimally tight, maximizing magnetic flux density and motor power factor. Simultaneously, we use oversized, low-friction sealed bearings (C3 or better) that reduce mechanical resistance and eliminate parasitic drag. Electrically, copper losses are minimized by selecting the optimal wire gauge and winding pattern for the target voltage, balancing the winding resistance against the current density. Every high-efficiency motor is verified on our in-house dynamometers, generating a full efficiency map (speed vs. torque vs. efficiency) that provides transparent, real-world data to our OEM clients, guaranteeing the 85%+ performance claim. This holistic engineering approach ensures every kilowatt-hour from the battery is maximized for driving distance.

Technical Specifications and Efficiency Mapping

The specifications for High Efficiency Hub Motors (85%+) are dominated by the material properties and design choices that directly impact energy loss. The table below details the key efficiency-driving components, followed by an explanation of how HENTACH validates and maps the real-world efficiency of the motor, providing the necessary assurance for battery sizing and range calculations for our B2B partners.

| Parameter | Value/Rating |

|---|---|

| Peak Efficiency (Validated) | ≥85% (Often >90% at optimum point) |

| Cruising Range Efficiency | Optimized for 85%+ across 20−40 km/h range |

| Stator Lamination Material | High-Grade Non-Oriented Silicon Steel (Low Core Loss) |

| Magnet Grade | High-Energy Neodymium (N45H or better) |

| Winding Optimization | Low Copper Resistance, High Fill Factor |

| Air Gap Precision | Controlled to ±0.1 mm via CNC Machining |

| Loss Minimization Focus | Iron Losses (Eddy Current/Hysteresis) and Copper Losses (I2R) |

| Validation Method | Full Dynamometer Efficiency Mapping (ISO Standard) |

The core material science lies in the High-Grade Non-Oriented Silicon Steel laminations. These laminations are manufactured at an optimal thickness (e.g., 0.35 mm or less) and subjected to specialized annealing processes that significantly reduce magnetic loss (iron loss). This is crucial because iron loss is constant regardless of the motor's load, becoming a major factor in inefficiency at cruising speeds. Furthermore, the motor utilizes High-Energy Neodymium (N45H or better) magnets, maximizing the magnetic flux density within the motor. A stronger, denser flux allows the motor to generate the required torque with less current, directly reducing copper losses (I2R) and boosting efficiency. The final electrical and mechanical assembly quality, confirmed by Precision CNC Machining, ensures the physical structure supports this optimized electromagnetic design. Every motor's performance is tested using a calibrated dynamometer, which generates a comprehensive efficiency map that plots efficiency as a function of torque and speed, allowing clients to accurately model the impact of the motor on their vehicle's range and battery life under real-world cycling conditions. This rigorous validation underpins our 85%+ efficiency guarantee.

Applications and Range Extension Benefits

The use of High Efficiency Hub Motors is strategic in any electric vehicle application where driving range, battery size, or thermal management are key performance constraints. The 85%+ efficiency rating provides tangible benefits in reducing both the vehicle's capital cost and its lifetime operating expenses, making it the preferred choice for commercial and premium consumer segments.

Premium and Long-Range E-Bikes: Direct range increase of 10%−20% compared to standard motors, allowing manufacturers to advertise market-leading range figures with the same battery size, or reduce battery size while maintaining competitive range.

E-Mopeds and L1e/L3e Vehicles: Efficiency is critical for highway-speed operation where continuous power draw is high. Lower losses mean lower operating temperatures, which is essential for motor and controller longevity in sustained high-speed use.

Shared Mobility Fleets (TCO Focus): Minimizes energy consumption, reducing the cost per mile for battery swapping or charging operations. Lower heat generation also improves component lifespan, directly lowering the Total Cost of Ownership (TCO).

Electric Utility and Cargo Vehicles: Maximizes the driving range under maximum payload, ensuring the vehicle can complete its commercial route without needing an oversized or prematurely depleted battery, improving operational efficiency.

We work with OEM partners to tune the motor's winding and controller parameters to maximize efficiency specifically within their vehicle's most frequent operational range (e.g., 25−35 km/h for commuter bikes), ensuring that the energy savings are realized in the conditions that matter most to the end-user, providing a clear competitive advantage in performance and range assurance.

Key Advantages: Range, Heat Reduction, and TCO

The competitive advantages of HENTACH's High Efficiency Hub Motors (85%+) stem from the fundamental law of energy conservation: what is not wasted as heat is converted into usable kinetic energy. This principle translates into a powerful combination of performance, thermal stability, and economic savings for the client and the end-user.

Significant Range Extension: The ≥85% efficiency rating directly means 5%−15% more of the battery's energy is used for driving compared to a standard 70%−80% motor, substantially increasing the vehicle's real-world range.

Lower Battery Cost and Weight: High efficiency allows the client to achieve the same target range with a smaller, lighter, and less expensive battery pack, reducing the vehicle's capital cost and improving handling.

Superior Thermal Management: Lower energy loss means less heat generation. A motor operating at 90% efficiency is generating half the heat of a motor operating at 80% efficiency. This dramatically reduces thermal stress, preventing the demagnetization of magnets and extending the lifespan of the windings and controller.

Consistent Performance: The low operating temperature ensures the motor maintains its peak power and torque output without suffering from thermal derating (throttling) under continuous use, guaranteeing consistent user experience.

Reduced Total Cost of Ownership (TCO): Less energy consumption per mile lowers utility bills for fleet operators and reduces battery strain, extending the battery pack's overall lifespan, contributing to a lower TCO.

Low Noise Profile: Efficiency improvements are often coupled with minimized vibration and reduced cogging torque, resulting in a smoother, quieter, and more natural riding experience, which is a key trait of premium e-mobility devices.

This commitment to high efficiency is a strategic investment in the long-term success of the client's product, delivering superior performance metrics that are both measurable and marketable to the end-consumer.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China High Efficiency Hub Motors (85%+) Manufacturers and China High Efficiency Hub Motors (85%+) Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体