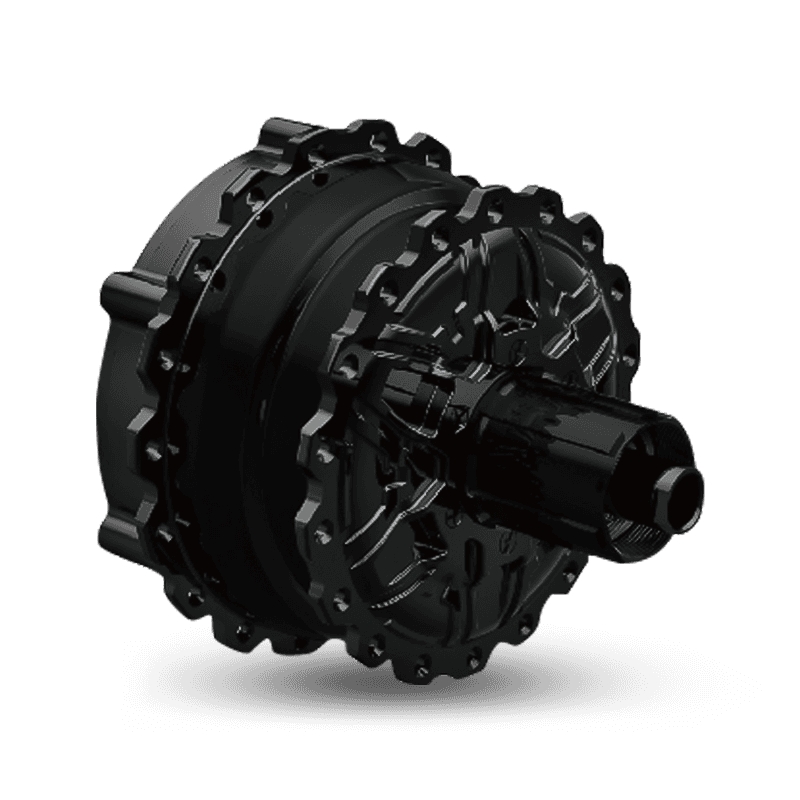

| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

High Efficiency E-Mobility Powertrains

-- Steady & Reliable Manufacturer --

Total System Optimization: The Philosophy of High-Efficiency Powertrains

In the competitive landscape of electric mobility, efficiency is the ultimate metric. At HENTACH, formerly known as Hengtai Motor, we define a High Efficiency E-Mobility Powertrain not just by the motor’s peak performance, but by the holistic synergy between electromagnetic design, mechanical transmission, and thermal management. Since 1995, our 9,000-square-meter facility has been dedicated to minimizing energy loss at every stage of the propulsion cycle. Efficiency in a hub motor is often lost through three primary channels: copper losses (heat in the windings), iron losses (magnetic hysteresis), and mechanical friction (gears and bearings). Over three decades of electromechanical innovation, HENTACH has developed proprietary solutions for each. By utilizing ultra-thin 0.35mm silicon steel laminations and high-fill-factor copper windings, we have pushed our motor efficiency peaks beyond 88%, ensuring that every watt of battery power is translated into maximum range for the end-user.

Our approach to powertrain development is rooted in vertical integration and industrial-scale manufacturing. Within our campus, we utilize 500-ton high-pressure die-casting machines to create motor housings that act as high-performance heat sinks. Rapid heat dissipation is critical; as a motor’s temperature rises, its internal resistance increases, causing efficiency to drop. By engineering the housing with optimized cooling fins and utilizing magnesium or high-grade ADC12 aluminum, HENTACH ensures that the powertrain maintains its "sweet spot" of efficiency even during long-distance hauls. This structural integrity is also what allows our motors to consistently exceed the 50,000-mile durability benchmark. A more efficient motor runs cooler, and a cooler motor lasts longer. This virtuous cycle of engineering is the hallmark of the HENTACH brand.

Furthermore, our high-efficiency systems incorporate our patented nylon-steel hybrid gears. Unlike standard all-metal gearboxes that suffer from significant mechanical drag, our hybrid system offers a self-lubricating interface that reduces internal friction by up to 15%. This contributes directly to a quieter ride and a more responsive acceleration curve. For B2B partners, choosing a HENTACH powertrain means providing a product that feels more refined and offers superior battery economy compared to generic alternatives. Our ISO 9001 certified facility ensures that this efficiency is consistent across every unit produced, from the first prototype to the 100,000th production motor. We are not just selling components; we are providing the professional-grade engineering foundation for the next generation of sustainable transportation.

Powertrain Performance and Efficiency Parameters

| Technical Metric | Specification Value | Performance Impact |

|---|---|---|

| System Peak Efficiency | ≥ 88% (Motor + Gearbox) | Maximizes Battery Range |

| Lamination Thickness | 0.35 mm Silicon Steel | Reduces Eddy Current Losses |

| Magnet Grade | N42SH (High Temp Resistance) | Maintains Flux at 150°C |

| Gearbox Friction Coeff. | < 0.08 (Patented Hybrid) | Reduces Mechanical Drag |

| Thermal Conductivity | 120 W/m·K (Aluminum Housing) | Prevents Efficiency Decay |

| No-Load Current | ≤ 0.8A (at 48V) | Minimal Internal Resistance |

| Phase Resistance | < 25 mΩ (Milliohms) | Reduces Copper Heat Loss |

| Torque-to-Weight Ratio | 12 Nm/kg | High Power Density Design |

| Winding Fill Factor | ≥ 92% (Precision Wound) | Optimized Current Density |

| Acoustic Signature | ≤ 48 dB (at Max RPM) | Smooth, Quiet Energy Transfer |

Strategic Applications for Efficient Propulsion

High-efficiency powertrains are the primary choice for Long-Range Urban Commuter Bikes, where extending the distance between charges is a key consumer selling point. In the crowded market of city mobility, vehicles powered by HENTACH systems often achieve 10-15% more range with the same battery pack as competitors. They are also essential for Solar-Assisted Electric Vehicles and delivery robots, where energy harvesting is limited and every milliwatt must be conserved. Our drive systems provide the reliability and efficiency required for 24/7 autonomous operation in smart city logistics.

- Premium Folding E-bikes requiring high power from small batteries.

- Last-Mile Delivery Robots with strict energy consumption targets.

- Electric Micro-mobility Fleets (Rental) focused on low operational costs.

- High-End Mobility Scooters for indoor/outdoor use.

- Electric Assisted Wheelchairs for long-distance independence.

The HENTACH Efficiency Advantage

The advantage of our high-efficiency systems lies in the Predictability of Thermal Performance. Most motors fail not because of mechanical breakage, but because of thermal runaway. By engineering for efficiency, HENTACH motors produce less waste heat, which protects the internal insulation and the Hall sensors from degradation. This is why our motors have historically proven to exceed 50,000 miles in the field. Our 30-year legacy of electromechanical innovation means we have mastered the art of "Cool-Running" motors. For a B2B partner, this translates to significantly lower warranty return rates and a brand reputation for bulletproof reliability.

Additionally, our Vertical Integration ensures that we control every factor affecting efficiency. From our in-house 500-ton die-casting of the housings to our precision CNC machining of the gear carriers, we eliminate the tolerances that lead to friction and noise. Our ISO 9001 certified quality control system utilizes dynamometer testing on every batch to verify that the efficiency curve matches our engineering specifications. When you partner with HENTACH, you are leveraging three decades of "Hengtai" excellence to deliver a powertrain that is objectively superior in performance and durability. We provide the professional engineering depth that allows your brand to stand out in a saturated market.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China High Efficiency E-Mobility Powertrains Manufacturers and China High Efficiency E-Mobility Powertrains Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体