| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

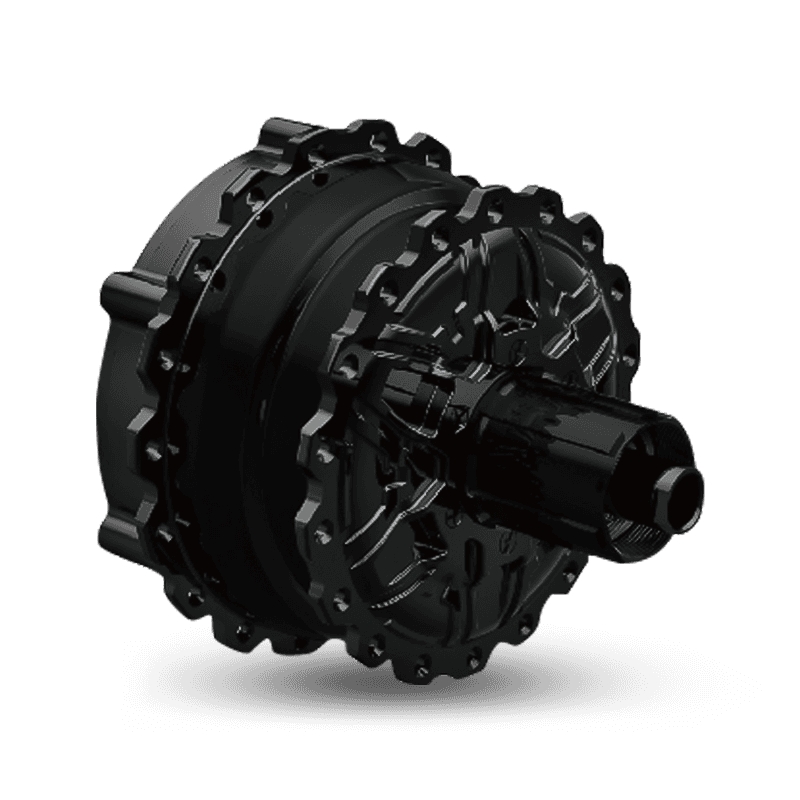

E-Bike Hub Motor Solutions

-- Steady & Reliable Manufacturer --

Introduction to High-Efficiency Hub Propulsion

The evolution of urban mobility has placed unprecedented demands on the core of the electric bicycle: the motor. As a manufacturer with over 30 years of electromechanical innovation, we have witnessed the transition from basic power units to the sophisticated E-bike hub motor solutions available today. Our facility, established in 1995, has dedicated decades to perfecting the balance between torque, weight, and thermal management. We understand that for an e-bike brand, the motor is not just a component; it is the promise of reliability given to the end-user.

Our current production lineup reflects a deep integration of raw material casting and precision processing. Unlike many assemblers, we maintain end-to-end control within our 9,000-square-meter campus. This allows us to implement a rigorous ISO 9001 quality control system at every stage, from the initial 500-ton die-casting of the motor housing to the final micro-arc oxidation coating. Whether you are developing a folding commuter bike or a high-performance mountain e-bike, our motor solutions are engineered to deliver a seamless, intuitive riding experience that meets international standards.

In recent years, the market has shifted toward high-torque density and low-noise operation. Our engineering team has responded by utilizing proprietary technology and high-grade materials. We have moved beyond standard industry benchmarks to ensure our motors can withstand diverse climates and terrains. This commitment to excellence is what defines our legacy as a trusted global manufacturer.

Technical Specifications

| Parameter | Value / Detail |

|---|---|

| Motor Type | Brushless DC (BLDC) Geared Hub Motor |

| Rated Power | 250W / 350W / 500W Options |

| Voltage Range | 36V / 48V DC |

| Max Torque | 45Nm - 65Nm |

| Efficiency | ≥ 82% |

| Noise Level | < 55dB |

| Waterproof Grade | IP65 / IPX6 |

| Surface Treatment | Micro-arc Oxidation / Powder Coating |

Typical Application Scenarios

Our hub motor systems are designed for versatility across the modern e-mobility landscape. Primary applications include Urban Commuter E-bikes, where compact size and low noise are critical for city navigation. They are also widely integrated into Folding Electric Bikes due to their lightweight aluminum-magnesium alloy construction, which facilitates easy transport without sacrificing power.

- Leisure and Trekking E-bikes requiring consistent long-range power.

- Electric Mountain Bikes (eMTB) needing high-torque assistance for climbing.

- Compact Electric Scooters utilizing miniature hub designs.

- Shared Mobility Fleets where durability and IP65 protection are mandatory.

Core Manufacturing Advantages

The primary advantage of our motor solutions lies in our Patented Nylon-Steel Gear technology. By combining the quiet operation of nylon with the structural integrity of steel, we achieve a lifespan that far exceeds standard all-plastic gear sets. Furthermore, our in-house die-casting capability ensures that every motor housing is structurally sound and optimized for heat dissipation, preventing power fade during extended use.

Our durability is not just a claim; it is a proven fact. We famously conducted a mileage guarantee program where motors were tested for over 30,000 miles. Over 50 of those units surpassed 50,000 miles of continuous operation without failure. This level of reliability reduces warranty claims for our B2B partners and enhances the brand reputation of the final vehicle.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China E-Bike Hub Motor Solutions Manufacturers and China E-Bike Hub Motor Solutions Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体