| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

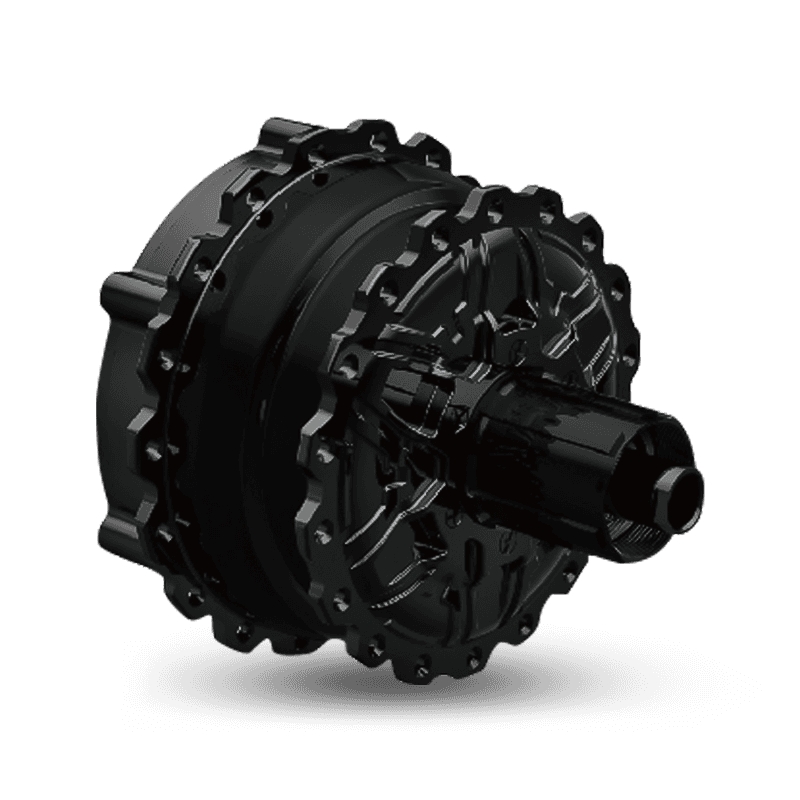

E-Moped Hub Motors

-- Steady & Reliable Manufacturer --

High-Performance Drive Systems: E-Moped Hub Motors

The E-Moped Hub Motor category demands a significant leap in power, durability, and thermal management compared to standard e-bike motors, as these vehicles operate at higher speeds, carry heavier loads, and often maintain sustained power output for longer periods. Our hub motors for E-Mopeds and L1e/L3e category vehicles are engineered to meet strict international standards for safety and performance, delivering reliable, silent, and highly efficient motive power. We focus on maximizing torque at the wheel rim to ensure rapid acceleration and excellent climbing capabilities, matching the performance expectations of internal combustion engine mopeds while offering superior environmental credentials.

A critical challenge in moped hub design is thermal dissipation. Operating at higher continuous power (often 3 kW to 5 kW peak) generates substantial heat. Our solution involves utilizing advanced outer-rotor motor architectures with enlarged cooling fins and, in high-power models, integrated forced air or oil-cooling channels within the hub shell. This proprietary thermal management ensures the motor can run reliably without derating, even in demanding urban traffic or under high ambient temperatures. The motor core uses high-saturation magnetic materials and precision winding techniques to achieve up to 92% peak efficiency, minimizing energy waste and maximizing the vehicle's crucial range metric.

Safety, Compliance, and Direct Drive Advantage

Due to the high speeds involved, safety and compliance are paramount. Our E-Moped Hub Motors are designed for compliance with major regulatory bodies (e.g., EEC, DOT), ensuring smooth market entry for our global OEM clients. The robust wheel hub design includes reinforced bearings and a high-strength chrome-moly axle, capable of handling the substantial side loads and shock forces encountered at speed. We primarily favor direct-drive BLDC hub motors for moped applications. The direct-drive design eliminates the complexity, noise, and wear associated with planetary gears, offering exceptional long-term reliability and a virtually maintenance-free operational life. This also enables powerful regenerative braking, significantly reducing wear on mechanical brake systems and contributing to the vehicle's overall energy efficiency.

HENTACH’s engineering extends to critical component integration, providing seamless compatibility with high-voltage controllers (48V to 72V and above) and sophisticated control algorithms like FOC (Field-Oriented Control) for ultra-smooth, high-torque starts. We offer full customization of wheel diameter integration, brake interfaces (drum or large-diameter disc), and specific electrical characteristics to perfectly match the performance envelope required by the E-Moped platform, ensuring our motors are the silent, powerful heart of the next generation of urban transportation.

Key Specifications and Advanced Technical Data

The specifications for E-Moped Hub Motors move beyond simple power ratings to focus on sustained power delivery, high-voltage compatibility, and crucial physical tolerances. The following table provides the core data points, followed by a detailed explanation of the high-performance materials and construction techniques employed to ensure the motor's suitability for high-speed, high-demand vehicle use. Our commitment to transparent, certified data allows B2B buyers to directly integrate our performance curves into their vehicle simulation models with confidence.

| Parameter | Value/Range |

|---|---|

| Motor Type | Direct Drive BLDC Outer Rotor Hub |

| Rated Power (kW) | 2.0 kW−5.0 kW (Continuous) |

| Peak Power (kW) | Up to 10 kW |

| Voltage (V) | 48V, 60V, 72V, 96V DC |

| Peak Wheel Torque (Nm) | 150 Nm−350 Nm |

| Efficiency (η) | ≥90% (Nominal Operation) |

| Cooling System | Natural Air / Internal Liquid-Cooling Option |

| Wheel Compatibility | 10-inch to 16-inch Rim Sizes |

The high efficiency rating (≥90%) is achieved through precision-balanced rotors and the minimization of magnetic flux leakage, which directly impacts the battery range of the final vehicle. The motor's construction utilizes a specialized high-tensile strength aluminum alloy for the hub shell, providing both exceptional heat transfer and the structural rigidity necessary for high-speed use. The axles are forged from high-grade alloy steel and designed with large-diameter cross-sections to handle the extreme vertical and torsional loads exerted by mopeds. Critically, the direct-drive design requires high-quality, large-diameter bearings, which are specified for high RPM and continuous-duty service life, sealed with IP67 protection for maximum longevity. For regulatory compliance, our motors are supplied with integrated high-resolution hall sensors and temperature sensors, allowing the controller to precisely govern the power output to meet specific speed and power limits mandated by L1e/L3e vehicle classifications. This technical attention to detail ensures superior durability and performance when compared to low-quality competitors, making HENTACH the reliable choice for performance-focused E-Moped manufacturing.

Key Applications and Commercial Deployment Niches

Our E-Moped Hub Motors are designed to serve a broad range of high-demand commercial and personal transportation applications, filling the space between e-bikes and full electric motorcycles. The key value proposition across all applications is the high-power-to-volume ratio combined with the maintenance-free nature of the direct-drive system, which is paramount for commercial profitability. The primary target applications demand specific performance tuning, which HENTACH provides through customized motor windings and voltage options.

-

Personal E-Scooters/Mopeds (L1e/L3e Category): Requires motors tuned for high acceleration (quick starts from traffic lights) and sustained cruising speeds (up to 45 km/h or more). The focus is on smooth, predictable power delivery and high-efficiency to maximize range.

-

Last-Mile Delivery Fleets (Food/Parcel): Commercial use demands S1 continuous duty cycles, extreme durability, and powerful hill-climbing torque. Our motors are built with oversized heat sinks and reinforced axles to survive the constant start-stop operation and heavy payloads typical of delivery work.

-

Ride-Sharing and Rental Fleets: Focuses on tamper-resistance, robustness, and the ability to integrate advanced communication systems (e.g., CAN Bus diagnostics) through the controller. The direct-drive system is favored here for its virtually zero maintenance requirement.

-

Light Utility and Campus Vehicles: Used in large campuses, resorts, or industrial sites for personnel and light cargo transport. Here, the motor's smooth low-speed control and high torque for small ramps are essential features.

We offer specific motor series for different performance tiers, from cost-effective 2 kW commuter units to performance-oriented 5 kW models. The versatility in wheel sizes (10-inch to 16-inch) and brake interfaces allows manufacturers to rapidly iterate on new vehicle designs. By providing high-quality, certified drive systems for these critical commercial niches, HENTACH supports the electrification of urban logistics and personal transport, offering a scalable and reliable supply chain solution for global vehicle assemblers.

Core Advantages: Efficiency, Durability, and Compliance

HENTACH E-Moped Hub Motors offer a decisive set of advantages, particularly for high-volume manufacturers where reliability, efficiency, and compliance directly impact final profitability and market acceptance. Our motors are optimized to provide superior performance compared to competing products, backed by rigorous testing and in-house manufacturing control. These are the key factors that differentiate our drive systems in the competitive high-power LEV market:

-

Exceptional Energy Efficiency (≥90%): Minimizes thermal losses and maximizes the vehicle's operating range per charge. This directly lowers the cost of ownership and improves the consumer appeal of the final product.

-

Maintenance-Free Direct Drive System: The absence of internal gears (common failure points in geared systems) ensures the motor requires zero scheduled mechanical maintenance, crucial for rental fleets and high-mileage users.

-

Integrated Regenerative Braking: Harnesses deceleration energy back into the battery, extending range and drastically reducing wear on the physical brake pads. This feature is fully controllable via the partnered controller system.

-

Superior Thermal Management: Proprietary hub design with increased surface area and optional internal cooling systems ensures sustained peak power delivery without dangerous overheating or thermal throttling, ensuring performance consistency.

-

Global Regulatory Compliance: Designed and tested to meet key international safety and vehicle classification standards (e.g., EEC L1e/L3e), simplifying the homologation process for OEMs targeting European and global markets.

-

Robust Physical Construction: Features forged alloy axles and reinforced hub shells that are built to handle high torque and the dynamic loads associated with two-wheel vehicle operation at speed, greatly enhancing product safety and longevity.

This combination of high technical performance and strict adherence to manufacturing quality positions our E-Moped motors as the premium, reliable choice for manufacturers aiming to deliver high-quality, high-performance electric vehicles. We back these advantages with complete documentation and a comprehensive B2B warranty package.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China E-Moped Hub Motors Manufacturers and China E-Moped Hub Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体