| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

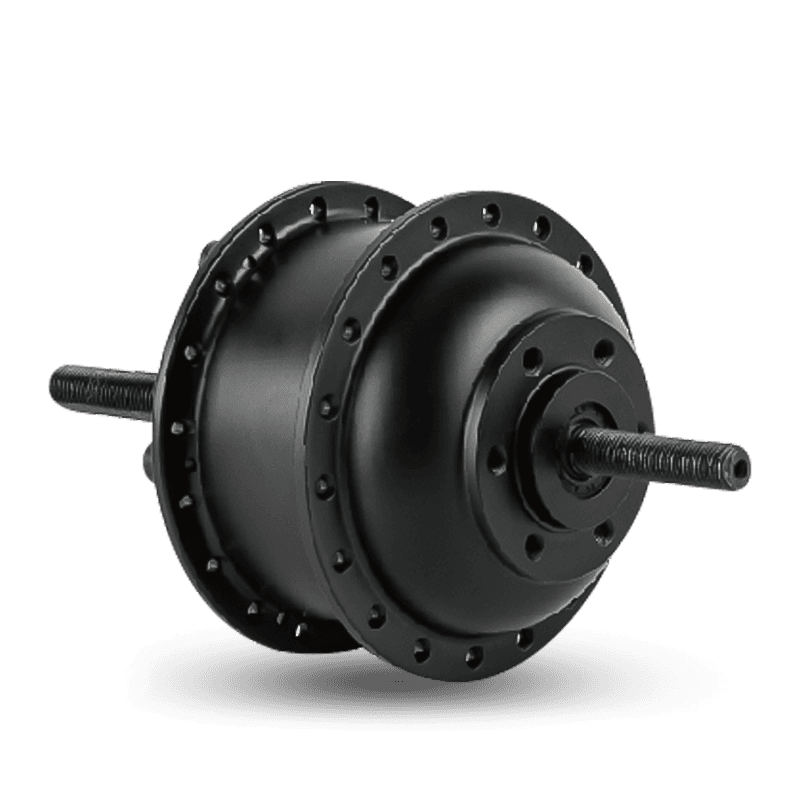

Electric Motorcycle Hub Motors

-- Steady & Reliable Manufacturer --

High-Velocity Engineering: The Evolution of Electric Motorcycle Propulsion

The transition from light e-bikes to full-scale electric motorcycles requires a fundamental shift in electromechanical philosophy. At HENTACH, formerly known as Hengtai Motor, we have spent the last 30 years mastering the high-torque, high-thermal-load environment of heavy-duty hub motors. Our Electric Motorcycle Hub Motors are not merely upscaled bicycle motors; they are ground-up engineering marvels designed to handle the rigors of highway speeds and sustained high-current draws. Operating within our 9,000-square-meter facility, our R&D team has developed a range of motorcycle-class drives that bridge the gap between urban commuting and performance racing. These motors are built using our 500-ton die-casting infrastructure, ensuring that the structural integrity of the motor housing can withstand the massive gyroscopic and braking forces inherent in a 150kg+ vehicle at speed.

Precision manufacturing is the heartbeat of our motorcycle series. Unlike smaller motors, a motorcycle hub must dissipate significant heat while maintaining peak efficiency. We utilize high-grade N42SH Neodymium magnets, which are rated for 150°C, and 0.35mm ultra-thin silicon steel laminations to minimize eddy current losses. This focus on material science allows our motors to maintain an efficiency peak of over 88%, even during aggressive acceleration. Our history in this sector is defined by our landmark durability tests. While the industry standard often stops at 10,000 miles, our motorcycle hubs were built to exceed the 50,000-mile mark. This longevity is achieved through our proprietary vacuum-impregnation of the stator windings, which protects against vibration-induced insulation failure and enhances thermal conductivity from the copper to the housing.

Furthermore, our motorcycle hubs feature reinforced axle geometries machined from 40Cr steel on our precision CNC centers. We understand that in a motorcycle, the motor axle is a critical suspension component. Our ISO 9001 certified process includes ultrasonic flaw detection for every axle to ensure no internal defects could lead to catastrophic failure. To protect these high-value components from the elements, we apply our signature Micro-Arc Oxidation (MAO) coating, which provides a ceramic-level barrier against the corrosive effects of road salts and high-pressure washing. For B2B partners, HENTACH offers a professional-grade powertrain solution that provides the silence of electric drive with the reliability of a 30-year manufacturing heritage. We don't just build motors; we build the future of two-wheeled transportation.

Motorcycle-Class Technical Parameters

| Technical Metric | Specification Value | Performance Focus |

|---|---|---|

| Rated Power Range | 3000W - 8000W (Continuous) | High-Speed Highway Capability |

| Peak Torque Output | 150Nm - 220Nm | Exceptional Gradeability (30%+) |

| Voltage Compatibility | 72V / 84V / 96V DC | Optimized for High-Current Flow |

| Magnetic Pole Pairs | 28 to 40 Poles | Smooth Torque Delivery |

| Winding Insulation Class | Class H (180°C) | Extreme Thermal Resilience |

| Axle Material | 40Cr Heat-Treated Alloy Steel | Structural Suspension Support |

| Phase Wire Gauge | 10mm² - 16mm² Teflon Insulated | Low Voltage Drop at High Load |

| Max RPM (at 72V) | 850 - 1200 RPM | Speeds up to 100-120 km/h |

| Brake System Support | Dual Disc Brake (Standard PCD) | Safety-Critical Integration |

| Rim Compatibility | 12" / 13" / 14" / 17" Integrated | Direct Casting for Rigidity |

Applications in Performance and Urban Mobility

Our motorcycle-grade motors are the primary choice for Electric Street Motorcycles and high-performance mopeds. In these applications, the motor must provide a linear power curve that mimics the feel of a traditional combustion engine while offering the instant torque characteristic of electric propulsion. They are also widely used in Electric Police and Emergency Vehicles, where reliability and low maintenance are paramount. The ability of our motors to operate silently makes them ideal for patrolling residential areas without causing noise pollution, while the 150Nm+ torque ensures they can navigate difficult urban terrain with ease.

- Electric Adventure Motorcycles for off-road and touring use.

- Heavy-Duty Delivery Motorcycles for logistics fleets.

- Commercial Cargo Trikes (Rear Drive pair) for urban freight.

- High-Speed Electric Scooters for regional commuting.

- Track-focused Electric Racing prototypes and hobbyist builds.

The Advantage of Heavy-Duty Engineering

The HENTACH advantage for electric motorcycles lies in our Integrated Casting and Machining. By using 500-ton die-casting for the entire motor hub and rim assembly, we eliminate the structural weaknesses associated with spoke wheels or bolted assemblies. This results in a much stiffer wheel that tracks better at high speeds and resists the deformation caused by potholes. Our 30-year history of electromechanical innovation has allowed us to perfect the balance between weight and strength. While our motors are built for power, we utilize magnesium and high-grade aluminum alloys to minimize unsprung weight, significantly improving the vehicle's handling and suspension response.

Moreover, our motors are "future-proofed" through our Advanced Thermal Management designs. Internal cooling fins and specialized airflow paths within the hub help move heat away from the magnets, preventing demagnetization even during long highway runs in summer temperatures. This reliability was proven when 50 of our motorcycle-class units surpassed 50,000 miles in continuous road testing. For B2B partners, this means partnering with an ISO 9001 certified manufacturer that understands the life-cycle of a vehicle. We provide the technical documentation, the performance consistency, and the industrial scale needed to bring a world-class electric motorcycle to market.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Electric Motorcycle Hub Motors Manufacturers and China Electric Motorcycle Hub Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体