| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

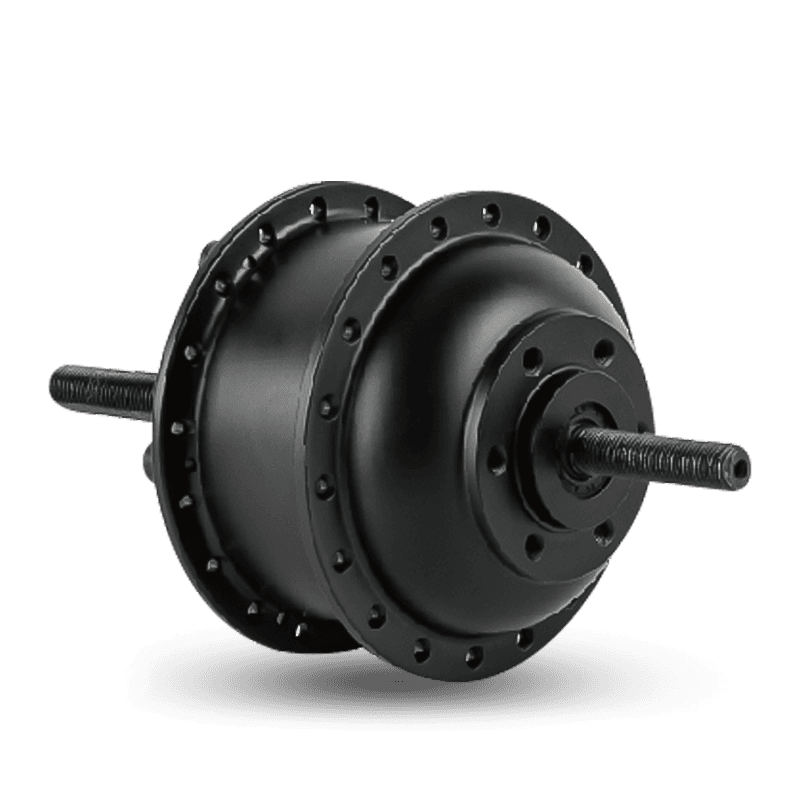

Electric Vehicle Hub Motors

-- Steady & Reliable Manufacturer --

Introduction

Our Electric Vehicle Hub Motors represent the pinnacle of our electromechanical engineering capabilities, specifically catering to the growing demand for powerful, reliable, and space-saving propulsion systems in various light and specialized EVs. Building on decades of experience (since 1995), we deliver robust hub motors suitable for applications far beyond e-bikes, including AGVs (Automated Guided Vehicles), golf carts, utility vehicles, and e-karting. These motors are engineered for higher load capacities, sustained output, and industrial-grade durability, setting them apart from standard consumer e-bike models.

For serious EV manufacturers, the critical concerns are thermal management, continuous power delivery, and the integration of robust braking systems. Our motors excel in these areas, featuring optimized aluminum alloy housings for superior heat dissipation and precision-machined components designed to withstand repetitive high-stress cycles. Our vertically integrated manufacturing process—from 500-ton die-casting of the housing to final motor test bench validation—ensures every unit meets rigorous international standards. We offer both front and rear-wheel drive solutions, compatible with various axle and chassis designs. Trust HENTACH (Hengtai Motor) for the power that keeps your commercial and industrial EVs moving reliably.

Specification

| Parameter | Range / Detail |

|---|---|

| Rated Power | 1.5 kW to 10 kW |

| Voltage Options | 48V, 60V, 72V, 96V |

| Peak Torque | Up to 250 N.m |

| Motor Type | High-Power BLDC Hub Motor |

| Cooling Method | Air Cooling (Standard); Liquid Cooling (Custom) |

| Load Capacity | Designed for loads up to 500 kg per axle |

| Braking | Compatible with Drum or Hydraulic Disc Brakes |

| Efficiency | > 90% at Rated Speed |

Applications

Automated Guided Vehicles (AGVs): Providing precise, maintenance-free drive systems for indoor logistics and warehouse automation.

Golf Carts & Utility Vehicles: Delivering consistent torque and speed for passenger and light-cargo transport across challenging terrains.

E-Karting & Recreational EVs: High-performance motors used in electric racing karts and recreational electric vehicles where immediate power response is necessary.

E-Cargo & Delivery Trikes: Robust drive units for urban delivery vehicles requiring high starting torque under full load.

Agricultural Machinery: Employed in small electric tractors and automated farming equipment requiring rugged, weatherproof drive units.

Advantages

Industrial-Grade Robustness: Built using heavy-duty winding and high-grade magnets to ensure performance under sustained, high-current operation typical of commercial EVs.

Optimized Thermal Management: Our in-house die-casting expertise allows us to design motor shells with superior finning and materials for rapid heat dissipation, preventing power reduction.

Full Traceability & Testing: Each unit is rigorously tested on our dedicated electric vehicle motor test benches to validate torque, speed, and efficiency curves.

High Load Bearing Design: Integrated with heavy-duty bearings and axle support systems designed to reliably handle significant vehicle weight and dynamic loads.

Custom High Voltage Options: Ability to customize windings for high voltage systems (up to 96V) to meet high-speed or long-range performance demands.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Electric Vehicle Hub Motors Manufacturers and China Electric Vehicle Hub Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体