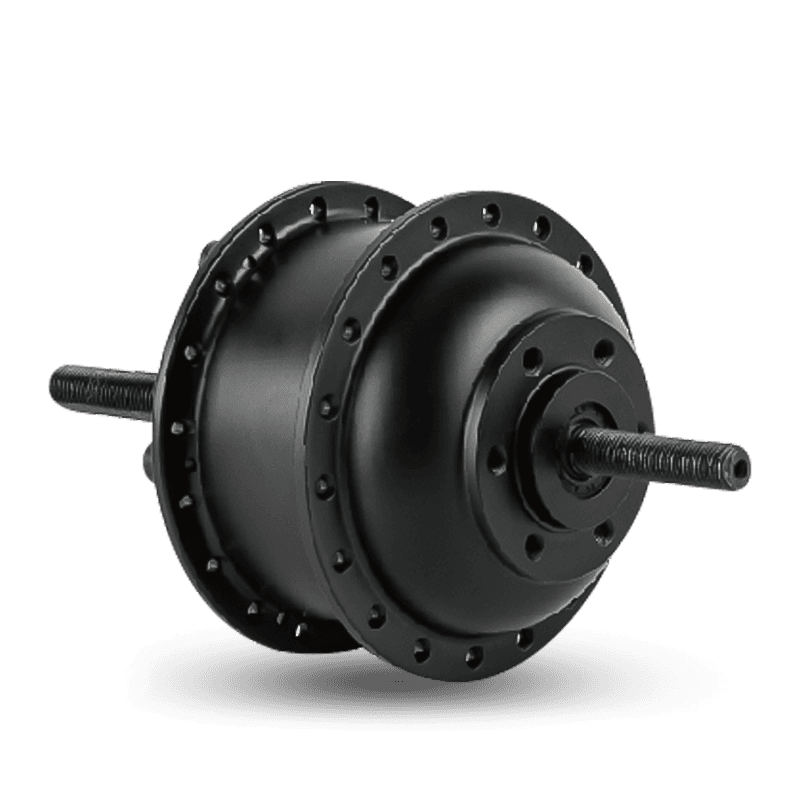

| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

Export-Quality Hub Motors China

-- Steady & Reliable Manufacturer --

Bridging Continents: The Standards of Global Hub Motor Export

China is the global center for electric mobility, but "export-quality" is a distinction that only a few manufacturers can truly claim. At HENTACH, formerly known as Hengtai Motor, our Export-Quality Hub Motors are the result of 30 years of continuous refinement and alignment with international standards. Since 1995, our 9,000-square-meter facility in Zhejiang has been focused on bridging the gap between high-volume manufacturing and Western quality expectations. We understand that export-grade products must be more than just powerful; they must be durable enough to survive thousands of miles of transit, compliant with various regional safety regulations (EN15194, UL 2849, CE), and backed by a professional-grade engineering heritage that simplifies the life of the global B2B partner.

Our commitment to export quality begins with our rigorous material selection. We do not use "market-grade" components. Every magnet in our export hubs is high-coercivity N42SH grade, and every winding uses Class H double-insulated copper. This ensures that the motor performs identically in the heat of Australia or the cold of Scandinavia. By utilizing our in-house 500-ton die-casting and precision CNC machining, we maintain tolerances that ensure our motors are proven to exceed a 50,000-mile durability benchmark. This longevity is the cornerstone of our "Hengtai" legacy; we build motors that act as a stable foundation for international brands to build their reputations upon. When a motor is exported, it must not come back for warranty repairs, as the logistics costs of international returns are prohibitive. HENTACH solves this through obsessive quality control.

Furthermore, our export-quality motors feature our patented nylon-steel hybrid gears. These gears are designed to provide the silent operation required by European and North American consumers, while maintaining the industrial-grade torque needed for heavy-duty applications. Our vertical integration allows us to apply advanced surface treatments like Micro-Arc Oxidation (MAO) to every unit destined for overseas markets, protecting them from the humid environment of sea transit and the corrosive road salts used in northern winters. Our ISO 9001 certified campus is audited regularly to ensure that our production lines meet the same high standards for every unit, from the first sample to the 100,000th production motor. We are the professional gateway for high-performance electric propulsion from China to the world.

Export Grade Technical Specifications

| Technical Metric | Specification Value | Export Advantage |

|---|---|---|

| Regional Compliance | EN15194 / UL 2849 / CE / RoHS | Ready for EU/NA Market Entry |

| Magnetic Stability | N42SH (Up to 150°C) | Reliable in All Global Climates |

| Cable Type | Marine-Grade Waterproof Connectors | Survives Salt Air During Sea Freight |

| Ingress Protection | IP65 / IP67 (Custom) | All-Weather Reliability Worldwide |

| Durability Rating | > 50,000 Miles (Tested) | Minimized International Warranty Cost |

| Acoustic Signature | ≤ 50 dB (Silent Gear Tech) | Meets Strict Urban Noise Regs |

| Phase Resistance | < 2% Phase-to-Phase Variance | Smooth, Efficient High-Speed Performance |

| Housing Material | ADC12 Aluminum (500-Ton Die-Cast) | Rugged Structural Integrity for Transit |

| Coating Type | MAO / Epoxy Powder Coat | Superior Corrosion Proofing |

| Quality Control | 100% Load & Dielectric Testing | Guaranteed Operational Excellence |

Applications for International Market Expansion

Export-quality motors are the primary choice for Global E-bike Brands who need a reliable OEM partner that understands the nuances of different regional markets. Whether it’s the 250W speed-limited motors for Europe or the high-torque 750W units for the US fat-tire market, HENTACH provides the tailored engineering needed. These motors are also vital for Fleet Rental Operators in major cities like Paris, London, and New York, where durability and ease of maintenance are critical for ROI. Our motors provide the industrial-grade reliability that allows international businesses to scale with confidence. By choosing HENTACH, you are choosing a 30-year legacy of export excellence.

- Premium Commuter E-bikes for the EU and US markets.

- Shared Micro-mobility Fleets requiring high-duty cycles.

- Electric Cargo Solutions for global logistics companies.

- Recreational Off-road vehicles for extreme climates.

- Medical and Rehabilitation equipment for international distribution.

The Advantage of a 30-Year Export Legacy

The primary advantage of HENTACH is Total Regulatory Peace of Mind. Navigating the world of international certification is difficult; our 30 years of electromechanical innovation mean we have already done the heavy lifting. We provide all the necessary documentation, test reports, and certifications to ensure your products pass customs and meet local safety laws without delay. Our 500-ton die-casting and ISO 9001 quality systems are optimized for the consistency that global brands demand. This is why our motors are proven to reach 50,000 miles of service; we engineer for the most demanding use cases in the world, ensuring that "Made in China" means "Industrial Excellence."

Furthermore, our Logistics and Supply Chain Expertise makes HENTACH more than just a vendor. We understand the complexities of global shipping, from managing container loading to providing specialized shock-resistant packaging that prevents transit damage. Our proximity to the Ningbo and Shanghai ports gives us a strategic advantage in shipping speed and cost. For B2B partners, this means a more resilient supply chain and a faster time-to-market. When you partner with HENTACH (Hengtai), you are leveraging three decades of professional-grade manufacturing to deliver superior value to your customers. We are committed to being the most reliable link in your international supply chain.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Export-Quality Hub Motors China Manufacturers and China Export-Quality Hub Motors China Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体