| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

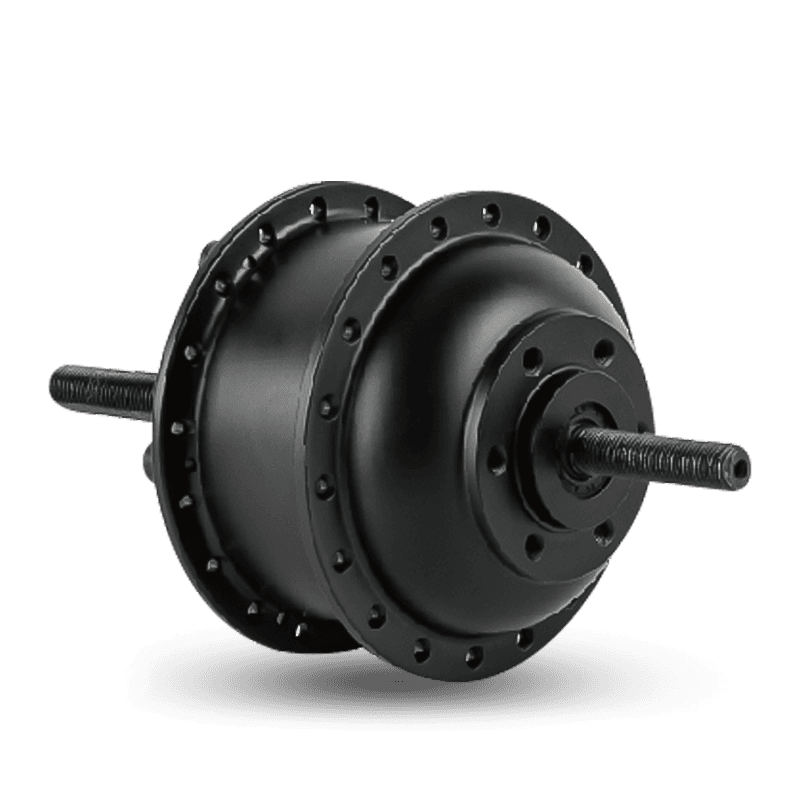

Integrated Controller Hub Motors

-- Steady & Reliable Manufacturer --

All-in-One Power: Integrated Controller Hub Motors

The Integrated Controller Hub Motor represents a significant advance in electric vehicle simplification, consolidating the motor drive unit and its sophisticated Electronic Control Unit (ECU) into a single, compact, and robust housing. This all-in-one design drastically reduces system complexity, simplifies wiring harnesses, minimizes electromagnetic interference (EMI), and accelerates the final vehicle assembly process for our OEM partners. By eliminating the need for bulky external controllers and complex cable routing, these units are ideally suited for space-constrained applications, such as lightweight e-bikes, folding bikes, and scooter platforms where aesthetics and ease of manufacture are paramount.

HENTACH’s engineering focuses on overcoming the primary challenge of integration: thermal management. Placing the heat-sensitive controller electronics inside the motor housing requires meticulous design to prevent thermal failure. We achieve this through proprietary techniques, including utilizing the motor's own aluminum housing as a dedicated, oversized heat sink for the controller's MOSFETs (metal-oxide-semiconductor field-effect transistors) and power stage. Furthermore, the controller firmware is deeply integrated and tuned to the specific motor's winding characteristics, resulting in highly efficient, optimized performance that minimizes power waste and heat generation, ultimately extending the service life of both the motor and the electronics.

System Simplicity and Smart Features

The value proposition of the integrated design for B2B partners is twofold: logistical simplicity and smart functionality. Logistically, the integrated unit replaces two separate components, reducing component inventory and eliminating production line errors associated with mismatched motors and controllers. Functionally, the integrated controller enables advanced features with minimal external wiring, such as instantaneous regenerative braking, self-diagnostics, and CAN Bus or Bluetooth communication for over-the-air (OTA) firmware updates and telemetry data logging. This smart capability is essential for modern connected fleets and premium consumer electronics.

We offer both geared and direct-drive integrated motor systems, catering to different application needs—geared for high low-speed torque (commuters) and direct-drive for silent operation and powerful regeneration (scooters). Our integrated solution provides a standardized, sealed, and reliable drive system that is quick to install, aesthetically pleasing, and technologically advanced, making it the ideal choice for manufacturers seeking to streamline production and deliver a cutting-edge electric vehicle product.

Structural Specifications and Embedded Electronics Details

The specifications for Integrated Controller Hub Motors must detail both the motor's mechanical parameters and the controller's electronic capabilities. The integration necessitates precise engineering to ensure thermal and electrical integrity. The following table provides the core combined data, followed by an explanation of the specialized electronics and thermal pathways that define the reliability of this advanced, all-in-one solution. We ensure rigorous testing of the full system—motor and controller together—to validate performance across the entire operating envelope, simplifying the client's certification process.

| Parameter | Value/Range |

|---|---|

| Motor Type | Geared or Direct Drive Hub Motor |

| Controller Integration | Fully Embedded (PCB/MOSFETs within Hub Shell) |

| Rated Power (W) | 250W - 750W (Nominal) |

| Voltage (V) | 36V, 48V DC Standard |

| Controller Type | FOC (Field-Oriented Control) Capable |

| Communication | UART / CAN Bus / Bluetooth Optional |

| IP Rating | IP65 (Standard) |

| Diagnostic Feature | Integrated Thermal Monitoring and Self-Diagnostic Ports |

The embedded controller is a high-reliability, automotive-grade Printed Circuit Board (PCB) utilizing high-temperature-rated MOSFETs and microcontroller units (MCUs). The FOC capability is critical, as it ensures the motor runs with minimal acoustic noise and maximum efficiency by precisely controlling the motor's magnetic field orientation. The electronics are fully protected by a specialized potting compound, providing IP65 ingress protection and excellent shock resistance against vibration. The integration features a direct thermal path: the controller's power stage is mounted onto a metallic surface that is thermally coupled to the motor's outer aluminum casing. This design ensures that the entire motor shell acts as a heat sink for the electronics, effectively managing heat generated by both the motor windings and the controller's switching losses. For communication, the motor supports standard UART or optional CAN Bus protocols, allowing manufacturers to integrate custom displays, diagnostic tools, and fleet management systems seamlessly through a single, secure external port. This integrated approach not only simplifies assembly but significantly enhances the long-term reliability of the entire drive system under real-world operating conditions.

Target Applications and Assembly Line Efficiency

The Integrated Controller Hub Motor is a powerful component for manufacturers prioritizing streamlined production, sleek aesthetics, and advanced connectivity features. Its application spans diverse categories where space is limited and system simplicity is a decisive competitive advantage. By offering a single component solution, HENTACH dramatically reduces the complexity and labor time required on the client's final assembly line.

-

Folding E-Bikes and Compact Commuters: The most critical application, where space for an external controller and complex wiring is minimal. The integrated design maintains a clean look and enhances portability.

-

High-Volume Shared Mobility/Rental Scooters: Ideal for fleet operators who need robust, tamper-resistant components with easy external connectivity for telemetry (GPS tracking, battery status). The integrated controller simplifies maintenance and component replacement.

-

Entry-Level/Retail E-Bikes: Reduces the cost and complexity of the bill of materials (BOM), leading to faster production cycles and higher gross margins. The simple plug-and-play architecture minimizes human error during assembly.

-

Modular E-Mobility Platforms: Used in customizable e-trikes or specialty devices where the drive system needs to be a self-contained, sealed unit, allowing the vehicle designer maximum flexibility in frame geometry and battery placement.

The integrated nature of the motor and controller facilitates the development of smart features for these applications, such as geo-fencing (controlling speed based on location) and remote diagnostic monitoring via the single communication line. HENTACH provides extensive B2B support, including custom tuning of the firmware parameters—such as acceleration curve, regenerative braking strength, and pedal assist levels—to perfectly match the final vehicle's performance characteristics and comply with all regional legal requirements (e.g., 25 km/h limit in Europe). This targeted integration support ensures a fast and reliable launch for new product lines utilizing our advanced, all-in-one drive systems.

Key Competitive Advantages of All-in-One Design

The competitive edge of an Integrated Controller Hub Motor stems from its revolutionary design simplification combined with high-performance electronics. These advantages translate directly into manufacturing efficiencies and superior user experience, setting our clients' products apart in a crowded market characterized by external components and complex wiring.

-

Drastic Reduction in Wiring Complexity: Replaces multiple cables and connectors with a single, highly-protected external connector. This significantly reduces assembly time, minimizes the chance of wiring errors, and improves the overall aesthetic of the bike.

-

Optimized Thermal Performance: Utilizing the entire aluminum motor shell as a dedicated heat sink for the controller's power stage, HENTACH achieves superior heat dissipation compared to externally housed controllers, preventing thermal derating and maximizing peak power duration.

-

Enhanced Environmental Protection (IP65/IP66): Encapsulating the sensitive electronics inside the sealed hub shell provides inherent protection against water, dust, and vibration, leading to dramatically reduced field failures and warranty claims.

-

Lowered Electromagnetic Interference (EMI): By shortening the high-current phase lines between the controller and the motor to mere millimeters, the integrated design minimizes EMI, preventing interference with other onboard electronics (GPS, display, communication modules).

-

Simplified Inventory and Logistics: Manufacturers deal with a single SKU for the drive unit instead of two (motor + controller), simplifying purchasing, inventory management, and quality control processes.

-

Custom FOC Firmware Tuning: The dedicated firmware allows for ultra-precise, customized tuning of the motor's power delivery curve, ensuring a smooth, natural riding feel that cannot be matched by generic external controllers.

This combination of manufacturing efficiency and sophisticated electronic control makes the Integrated Controller Hub Motor the definitive choice for next-generation electric mobility devices where compact size, reliability, and advanced smart features are paramount to market success.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Integrated Controller Hub Motors Manufacturers and China Integrated Controller Hub Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体