| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

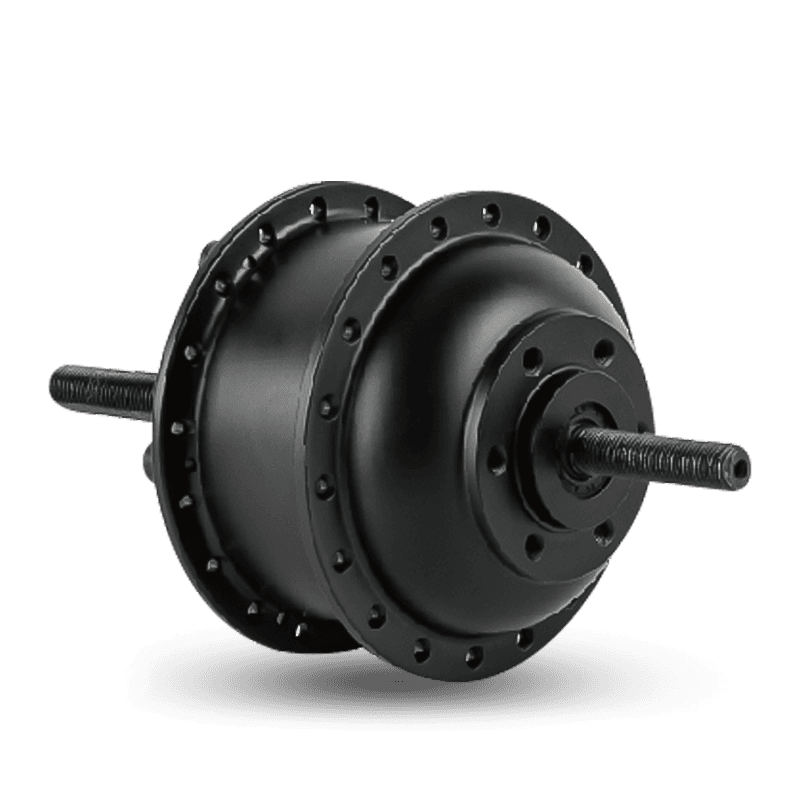

Brushless DC (BLDC) Hub Motors

-- Steady & Reliable Manufacturer --

The Standard for Modern Hub Drive Technology

The brushless DC (BLDC) hub motor has revolutionized the light electric vehicle (LEV) market, offering a level of efficiency, reliability, and power density that was once thought impossible. By eliminating the friction-prone brushes of traditional DC motors, BLDC technology provides a maintenance-free life cycle and a significantly higher power-to-weight ratio. As a specialized manufacturer established in 1995, we have spent nearly three decades perfecting the design of these motors. From our early days as "Hengtai Motor" to our current global presence, our focus has always been on the precision casting and electromechanical innovation required to make a hub motor that doesn't just work, but lasts for tens of thousands of miles.

At the heart of our BLDC hub motors is a sophisticated internal architecture. We utilize high-grade Neodymium (NdFeB) magnets and high-density copper windings to ensure maximum electromagnetic flux. Our 9,000sqm manufacturing campus includes dedicated vacuum-impregnation lines for our windings, ensuring they are protected against moisture and vibration. This attention to detail is what allows our motors to achieve efficiency ratings exceeding 85%, extending the range of any vehicle they are installed on. Whether it is a 250W city commuter or a 1000W high-torque cargo motor, the fundamental principles of quality remain the same: superior materials and precision manufacturing.

Innovation is part of our DNA, as evidenced by our Patented Nylon-Steel Gear design found in our geared BLDC hub units. This hybrid gearing provides the quiet, smooth ride of nylon with the rugged durability of steel, effectively solving the "weak point" found in many competitive geared motors. We believe in our engineering so much that we once launched a 30,000-mile guarantee program—a test that our motors didn't just meet, but many units exceeded by reaching the 50,000-mile mark. For B2B partners, this means a product that has been proven in the real world and is backed by an ISO 9001 quality management system.

Technical Hub Motor Specifications

| Technical Parameter | Standard Specification | B2B Advantage |

|---|---|---|

| Motor Configuration | Inner Rotor / Outer Rotor Hub | Flexible for different wheel sizes |

| Efficiency Peak | 85% - 90% | Extends battery life significantly |

| Hall Sensor Angle | 120 Degree Phase Angle | Standard compatibility with controllers |

| Gear Ratio (Geared) | 1:4.4 to 1:5 | Optimized for high-torque startups |

| Pole Pairs | 10 / 16 / 20 Poles | Smooth low-speed torque delivery |

| Thermal Protection | Integrated Thermistor (NTC 10K) | Safety for high-load applications |

| Wiring Exit | Axle Center / Axle Side | Customizable for frame dropouts |

| No-Load Current | < 1.2A | Low energy waste at cruising speed |

| Winding Material | 100% Oxygen-Free Copper | Maximum conductivity/efficiency |

| Magnet Grade | SH Grade (150°C Tolerance) | High heat resistance for steep hills |

Wide-Ranging Mobility Applications

Our BLDC hub motors are the "workhorse" of the light electric mobility world. Their primary application is in the Electric Bicycle (E-Bike) market, where they provide silent, intuitive pedal assistance. They are also widely used in Electric Scooters and personal mobility devices where space is at a premium and reliability is non-negotiable. Because the motor is integrated directly into the wheel, there are no chains or belts to maintain, making them the perfect choice for consumer-facing vehicles that need to remain "maintenance-free" for the duration of their lifespan.

- City and Commuter E-bikes (250W-350W versions).

- Electric Cargo Bikes requiring heavy-load geared hub motors.

- Foldable Electric Scooters for the "last-mile" urban commute.

- Electric Wheelchairs and medical mobility aids.

- Lightweight Electric Delivery Trikes for couriers.

The Engineering Advantage of Brushless Systems

The core advantage of our BLDC hub motors lies in the Integration of Material Science and Mechanical Engineering. By using our 500-ton die-casting machines to create aluminum-magnesium alloy housings, we solve the problem of weight while providing a natural heat sink for the internal electronics. This material choice, combined with our precision CNC processing, ensures that the motor remains concentric and balanced, reducing noise and vibration even at high speeds. Our silent operation is a key selling point for high-end LEV brands.

Furthermore, our durability story is unmatched in the industry. The fact that 50 of our motors surpassed 50,000 miles in field testing is a testament to our proprietary internal designs. From the quality of the silicon steel to the precision of the micro-arc oxidation surface treatment, every element is designed to resist the wear and tear of daily use. We don't just assemble motors; we engineer them from the ground up to be the most reliable component of your vehicle. Backed by 30 years of history, HENTACH is the name that global brands trust for their high-performance hub drive needs.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Brushless DC (BLDC) Hub Motors Manufacturers and China Brushless DC (BLDC) Hub Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体