| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

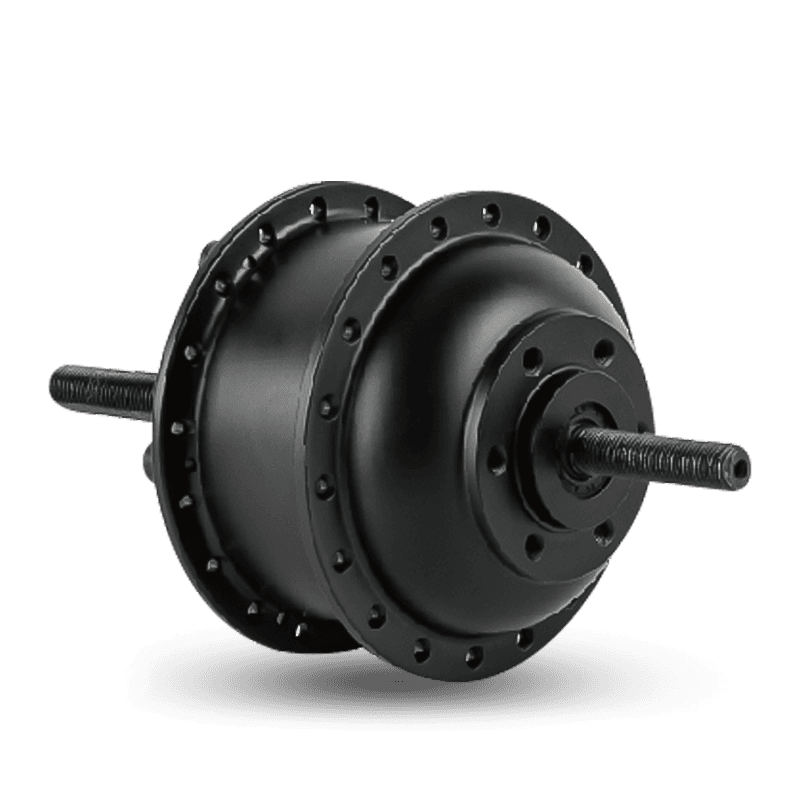

High Durability Hub Motors (40,000km+ Life)

-- Steady & Reliable Manufacturer --

Engineered for Endurance: High Durability Hub Motors (40,000km+ Life)

For commercial fleets, shared mobility providers, and high-mileage commuters, the true measure of quality lies in longevity and unwavering performance under continuous, high-stress use. Our High Durability Hub Motors are designed not just for standard service, but to exceed the most demanding durability expectations, ensuring a minimum service life of over 40,000 kilometers (or equivalent operational hours) without requiring scheduled maintenance. This exceptional lifespan is made possible by our rigorous design process, which incorporates premium materials, cutting-edge bearing systems, and sophisticated thermal management. These features make our hub motors the ideal solution for applications where downtime directly translates into lost revenue.

Overcoming the Two Primary Causes of Motor Failure

The challenge of achieving such extended durability comes down to addressing the two primary causes of motor failure: bearing wear and thermal degradation. At HENTACH, we've developed an effective solution to these problems by incorporating oversized, double-sealed C3-rated industrial bearings that are pre-packed with long-life, high-temperature grease. This advanced bearing system protects against contaminants, moisture, and excessive frictional heat, all of which are common causes of premature wear. Unlike consumer-grade motors, our bearings are chosen specifically for their high dynamic load rating, which means they can endure the constant shock, vibration, and heavy loads of urban or off-road environments. They’re built to withstand tens of thousands of kilometers of operation under challenging conditions.

To further enhance performance, our motor windings use high-temperature magnet wire and the highest-grade permanent magnets available. These materials are specifically selected to maintain their magnetic strength and operational efficiency even under prolonged, high-current operations. This ensures that the motor continues to deliver consistent power and torque, year after year, without performance degradation.

Advanced Thermal Management for Maximum Longevity

Efficient thermal management is essential for ensuring motor longevity, especially in high-stress environments. Our High Durability Hub Motors are equipped with proprietary die-cast aluminum housings, designed with optimized geometries that maximize surface area for passive heat dissipation. This innovative design ensures that the motor operates well within its thermal limits, even during continuous-duty cycling, thereby preventing the heat-induced baking of insulation and magnets that leads to premature failure. This means your fleet stays operational even in the hottest, most demanding environments.

Additionally, our motors are sealed to at least IP66 standards, employing dual-lip axle seals and potted cable exits to ensure maximum protection against water spray, road salt, fine dust, and mud. These are the primary environmental threats to the longevity of vehicle components, and we take every step to make sure our motors are safeguarded from them. Every batch of motors undergoes a rigorous life-cycle test on our in-house dynamometers, simulating years of operational use to guarantee they meet or exceed the 40,000km+ durability benchmark.

Customizable Performance for High-Impact Applications

We offer customization in terms of voltage (ranging from 48V to 72V) and power output (up to 1500 W continuous) to cater to the specific demands of heavy-duty applications like delivery fleets and shared e-scooters. By choosing HENTACH, you're investing in a motor system that delivers long-term, low-maintenance performance, reducing the need for costly repairs and minimizing warranty claims. This translates into a significantly lower total cost of ownership (TCO) for your electric fleet, ensuring that your business operates efficiently and profitably for years to come.

The HENTACH High Durability Hub Motor is the ultimate solution for businesses that need reliability, high-performance, and unbeatable longevity—a key to maximizing uptime and reducing the operational cost of electric fleets.

Key Specifications and Endurance Validation Metrics

The specifications for our High Durability Hub Motors are defined by metrics that prove long-term survival, not just peak power performance. The data below highlights the critical factors related to component strength, sealing integrity, and validated life-cycle endurance. Following the table is a detailed breakdown of the unique materials and testing protocols that substantiate the 40,000km+ claim, essential information for fleet managers and engineering teams focused on minimizing operational risk over time.

| Parameter | Value/Rating |

|---|---|

| Target Mileage Life | ≥40,000 km (Validated) |

| Bearing Type | Oversized C3-Rated Double-Sealed Industrial Ball Bearings |

| IP Rating | IP66 (Dust-tight and strong water spray protection) |

| Housing Material | Heavy-Duty Die-Cast A380 Aluminum Alloy |

| Winding Wire Rating | 180∘C High-Temperature Enamel Magnet Wire |

| Magnet Grade | High-Coercivity Neodymium (N38UH or better) |

| Axle Material | Heat-Treated Cr-Mo Alloy Steel |

| Thermal Management | Optimized Fin Geometry and Internal Temperature Sensor |

The 40,000 km+ Life Validation is achieved through accelerated lifetime testing, where motors are subjected to continuous duty cycles under maximum rated load, thermal cycling, and continuous vibration on specialized test rigs. The use of C3-rated industrial bearings is critical; these are selected because they are designed for high running accuracy at higher operating temperatures and loads than standard bearings, providing the necessary resilience for continuous duty. The motor's electrical resilience is assured by using 180∘C rated magnet wire, which retains its insulation integrity even when the motor briefly peaks at elevated temperatures, preventing inter-winding shorts. Furthermore, the high-coercivity Neodymium magnets (N38UH or better) are chosen for their superior resistance to demagnetization under thermal stress, ensuring the motor maintains its efficiency and power output over its entire service life. The entire electrical system is protected by a high-strength aluminum housing that acts as a structural and thermal shield. This focus on premium, over-engineered components and rigorous, validated testing is the core principle behind the exceptional durability of these motors, translating directly into reliable field performance for high-mileage fleets.

Core Applications in High-Mileage Fleets and Services

The demand for High Durability Hub Motors originates primarily from commercial sectors where vehicle utilization is high, environmental exposure is constant, and the cost of vehicle downtime is prohibitive. These motors are specifically engineered to endure the abuse and high cycling rates of fleet operation, offering a superior return on investment compared to standard consumer-grade motors. Our application focus is on providing robust, long-lasting drive systems that maintain performance integrity across extreme mileage counts.

-

Shared Mobility Fleets (E-Bikes and E-Scooters): These vehicles operate almost 24/7, face weather exposure, and endure high user abuse. The 40,000km+ life rating is vital for minimizing maintenance calls and maximizing the operational lifespan of the core vehicle asset.

-

Last-Mile Delivery Vehicles (E-Cargo & E-Mopeds): Daily usage often exceeds 100 km per vehicle, requiring exceptional component longevity. The durability and robust IP rating protect the motor from continuous exposure to rain, road grime, and salt, which quickly degrade lesser components.

-

Heavy-Duty Utility E-Bikes and Trikes: Used for industrial facilities, campuses, or agricultural logistics, where the vehicle often carries maximum load. The motor's heavy-duty axle and bearing system ensure structural integrity under constant high stress.

-

High-End Commuter E-Bikes: Targeted at premium consumers who demand absolute reliability for daily, all-weather commuting. The sealed design provides a maintenance-free experience, justifying the motor's higher quality component cost.

For these applications, we customize the motor to integrate seamlessly with fleet management systems, often including specific connectors and sensors (e.g., thermal reporting, tamper detection) that feed critical data back to the central operational hub. By focusing on longevity and robustness, HENTACH provides the foundational hardware that makes high-utilization electric mobility business models financially viable and scalable, offering OEM clients the confidence to back their products with industry-leading warranties.

Key Advantages: TCO Reduction and Field Reliability

The primary advantage of HENTACH's High Durability Hub Motors is the substantial reduction in the Total Cost of Ownership (TCO) for fleet operators and manufacturers. By designing for an extreme service life of 40,000 km and beyond, we minimize the expense and operational disruption associated with warranty claims, component replacement, and vehicle downtime, providing a highly reliable and profitable solution.

-

Industry-Leading Lifespan: A validated 40,000km+ service life reduces the required replacement cycle by 2x to 4x compared to standard motors, directly lowering component purchasing costs over the fleet's lifetime.

-

Minimal Warranty Exposure: The use of over-engineered components and rigorous quality control results in near-zero component failures in the first 40,000 km, drastically reducing the financial burden and reputational damage of warranty claims for the OEM.

-

Superior IP66 Environmental Protection: The advanced sealing protects internal components from water, road salt, dust, and grime, ensuring reliable operation in all weather conditions, which is essential for high-utilization commercial fleets.

-

Zero-Maintenance Bearing System: Oversized, permanently sealed C3 industrial bearings eliminate the need for scheduled lubrication or inspection, streamlining fleet maintenance protocols and labor costs.

-

Consistent Performance: High-temperature-rated windings and magnets maintain their power and efficiency output over the long term, preventing the gradual performance degradation often seen in lower-grade motors.

-

Enhanced Fleet Uptime: Reliability is the most critical factor for commercial operations. By eliminating component failure as a cause of downtime, our motors ensure maximum vehicle availability and revenue generation.

This commitment to engineering excellence and long-term reliability provides a clear competitive edge, allowing our OEM partners to offer market-leading TCO models and build customer trust based on the proven longevity of the motor drive system.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China High Durability Hub Motors (40,000km+ Life) Manufacturers and China High Durability Hub Motors (40,000km+ Life) Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体