| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

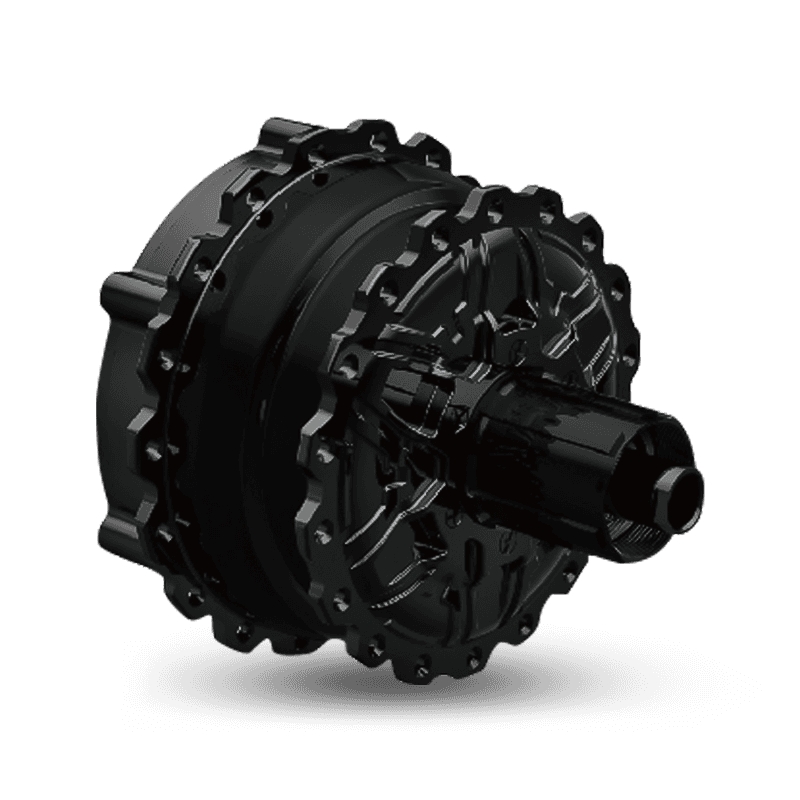

E-Cargo Bike Hub Motors

-- Steady & Reliable Manufacturer --

The Driving Force of Urban Logistics: Heavy-Duty E-Cargo Bike Hub Motors

The global shift towards sustainable last-mile logistics has positioned the electric cargo bike as an indispensable tool for urban commerce. This rapid evolution, however, places immense and unique demands on motor technology. Standard e-bike motors simply cannot withstand the continuous, high-stress load cycles required for commercial delivery fleets. At Ningbo Yinzhou HENTACH Electromechanical, we specialize in manufacturing E-Cargo Bike Hub Motors that are engineered not just for assistance, but for reliable, sustained, and heavy-duty performance under challenging operational conditions. These are motors built for business continuity, where uptime and payload capacity directly impact profitability.

Our engineering philosophy for cargo motors centers on three pillars: Unmatched Torque, Thermal Resilience, and Structural Durability. Cargo bikes often operate at the limit of their gross vehicle weight (GVW), frequently starting and stopping on inclines, which generates significant heat and stress within the motor core. Our proprietary design utilizes advanced magnetic steel and high-temperature-rated copper windings, maximizing torque density to ensure smooth starts even when fully loaded. The robust stator and rotor configuration minimizes energy loss and thermal build-up, guaranteeing that the motor can run continuously throughout a delivery shift without derating performance.

The HENTACH Difference: Engineering for Endurance

A critical component in any geared hub motor is the internal planetary gear system. Recognizing the inherent weakness of standard polymer gears under high stress, HENTACH developed a Plastic-Steel Composite Gear Technology. This innovation combines the noise-dampening benefits of high-grade engineering plastic with the sheer strength of precision-machined steel at the critical stress points. This results in a drivetrain that offers a longer lifespan (often exceeding 40,000 km in fleet use), significantly reduced acoustic noise for quiet urban operation, and far greater resistance to shock loads and fatigue cycling. This technological superiority is a key differentiator for serious OEM cargo bike manufacturers.

Furthermore, the axle assembly is critically reinforced. Cargo motor axles must withstand not only motor torque but also immense vertical load and lateral stress from cornering with heavy payloads. We employ high-strength Chromium-Molybdenum (Cr-Mo) steel axles, heat-treated and precision-machined in-house using our advanced CNC capabilities. This level of in-house control over the material and machining process ensures a flawless fit and maximum structural integrity, minimizing the risk of axle shear, a common failure point in inferior cargo motor designs. Our motor casings are produced using high-pressure aluminum die casting, providing a rigid, lightweight, and efficient housing that doubles as a heat sink.

Customization and B2B Partnership Value

For OEMs operating in diverse international markets, customization is non-negotiable. Our manufacturing agility allows us to offer motors tailored to specific regional regulations (e.g., 25 km/h limits, 1000W+ off-road power) and vehicle architectures (e.g., three-wheel vs. two-wheel, front vs. rear mount). We provide flexibility in winding configurations to optimize the motor for specific top-speed/torque trade-offs, depending on whether the customer prioritizes climbing ability or cruising speed. We also offer integrated sensor options (speed and temperature) and CAN Bus communication capabilities for seamless integration with advanced fleet management systems and controllers. Choosing HENTACH means partnering with a manufacturer that provides a robust, proven, and fully customizable drive system, ready to meet the rigorous demands of the global logistics revolution. Our commitment to ISO 9001 standards ensures every batch of E-Cargo Bike Hub Motors maintains the consistency and quality required by large-scale commercial integrators.

Key Specifications Table

| Parameter | Value/Range |

|---|---|

| Motor Type | Brushless Geared Hub Motor |

| Rated Power (W) | 500W - 1200W |

| Peak Torque (Nm) | ≥90 Nm |

| Voltage Compatibility | 48V/60V DC |

| Weight (kg) | 4.5 - 7.0 kg |

| Axle Material | High-Strength Cr-Mo Steel |

| IP Rating | IP65 (Dustproof & Water-Resistant) |

| Brake Type | Disc Brake Compatible (6-bolt) |

Primary Applications

-

Last-Mile Delivery Fleets: Ideal for couriers, food delivery, and logistics services in dense urban environments.

-

Commercial Utility Vehicles: Powering service bikes, mobile workshops, and municipal clean-up vehicles.

-

Heavy Load Transport: Used in specialized 3-wheel and 4-wheel cargo bikes for transporting goods up to 250kg payload.

Key Competitive Advantages

-

High Thermal Endurance: Advanced winding insulation and proprietary cooling design prevent overheating during prolonged, high-load operation.

-

Plastic-Steel Gear Technology: Incorporates robust internal gears that minimize noise while offering superior wear resistance compared to traditional nylon gears.

-

Reinforced Axle & Shell: Built with high-strength alloy castings to withstand the constant stress of heavy loading and rough commercial use.

-

Customizable Winding: Available for specific speed and torque profiles to meet unique fleet requirements.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China E-Cargo Bike Hub Motors Manufacturers and China E-Cargo Bike Hub Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体