| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

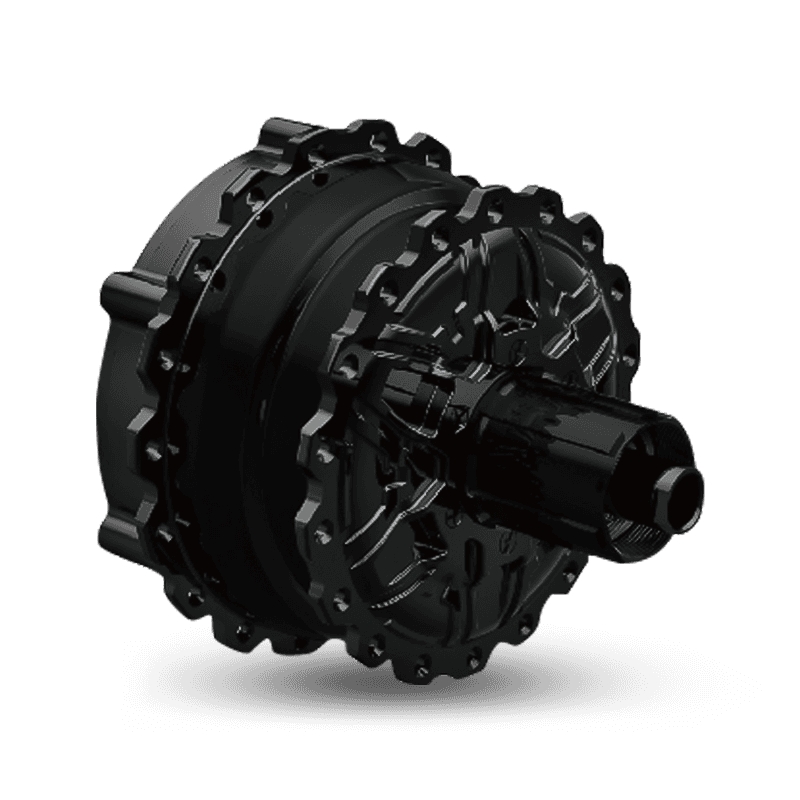

E-Cargo Vehicle Motors

-- Steady & Reliable Manufacturer --

Introduction

Powering the last mile and heavy-duty urban logistics is the purpose of our E-Cargo Vehicle Motors. As the global focus shifts towards sustainable and efficient urban transport, electric cargo vehicles (tricycles, four-wheeled light utility vehicles, and heavy-duty e-bikes) require drive systems that can handle significantly higher payloads and sustained climbing requirements compared to standard e-bikes. HENTACH (formerly Hengtai Motor) applies its extensive experience in durable electromechanical solutions to design and manufacture motors specifically optimized for this taxing operational environment. Our E-Cargo Vehicle Motors are characterized by immense low-end torque, robust gear reduction systems, and superior thermal stability to ensure reliability when carrying hundreds of kilograms of cargo.

For fleet operators, last-mile delivery companies, and OEMs specializing in urban utility vehicles, the key purchasing factors are hill-climbing ability, thermal longevity under continuous load, and system durability that resists frequent stop-start cycles. To meet these demands, we typically integrate high-power Brushless DC (BLDC) technology with heavy-duty gear reduction systems (often employing our patented nylon-steel hybrid gears for optimal strength and noise control) to maximize output torque. Thermal management is paramount; prolonged climbing under full load generates substantial heat. We address this by using larger, specialized motor magnetics and high-conductivity aluminum die-cast housings (made in-house using our 500-ton machines) to rapidly dissipate heat and prevent thermal failure, ensuring the motor maintains its rated power throughout the delivery route. Furthermore, our motors are built with oversized bearings and heavy-duty shafts to reliably handle the high radial loads exerted by large wheels and heavy cargo.

HENTACH’s E-Cargo Vehicle Motors are available in various configurations, including specialized hub motors and powerful mid-drive units, to suit different vehicle chassis designs. We offer customization for various battery voltages (48V, 60V, 72V) to match fleet standardization and range requirements. Every motor adheres to our stringent ISO 9001 quality system, undergoing vigorous load testing on our dedicated test benches to validate performance under simulated full-load conditions. The proven durability, a hallmark of our brand (demonstrated by motors that have surpassed 50,000 miles in real-world use), makes HENTACH the trusted supplier for reliable, high-torque propulsion systems necessary for the efficient and sustained operation of your electric cargo fleet.

Specification

| Parameter | Range / Detail |

|---|---|

| Motor Type | High-Torque BLDC (Hub or Mid-Drive) |

| Rated Power | 500W to 3000W |

| Voltage Options | 48V, 60V, 72V (High Power Battery Systems) |

| Peak Torque | 100 N.m to 350 N.m (Optimized for Hill Climbing) |

| Gearbox Type | Heavy-Duty Planetary or Integrated Reduction System |

| Housing Material | Custom Aluminum Die Casting (Optimized Cooling) |

| Ingress Protection | IP65 Rated (Weatherproof for Urban Environments) |

| Braking System | Compatible with Hydraulic Disc Brakes and Drum Brakes |

| Load Capacity | Designed for Vehicle Gross Weights up to 1000 kg |

Applications

Last-Mile Delivery Trikes: Providing robust, reliable power for three-wheeled electric vehicles carrying parcels and groceries in dense urban areas.

Light Electric Utility Vehicles: Powering municipal service vehicles, campus shuttles, and light maintenance vehicles with varying payloads.

Heavy-Duty Cargo E-Bikes: Integrated drive systems for specialized two- and three-wheeled cargo bikes designed for commercial use.

Food Service and Vending Carts: Reliable propulsion for mobile food vendors and vending systems that require substantial load-carrying capability.

Port and Industrial Transport: Used in small electric platforms and tow vehicles within ports, factories, and exhibition centers.

Advantages

Exceptional Hill-Climbing Torque: Engineered with high-reduction ratios and powerful magnetics to ensure reliable ascent even with maximum rated payload.

Superior Thermal Stability: Custom die-cast aluminum housings and optimized internals prevent heat build-up under continuous high-current draw, preventing power fade.

Industrial-Grade Durability: Heavy-duty shafts, sealed bearings, and robust gear systems ensure the motor withstands the constant stress of stop-and-go commercial operation.

Weather and Environmental Protection: IP65 rating provides comprehensive protection against rain, road spray, and dusty conditions typical of urban logistics.

Efficient Battery Usage: High-efficiency BLDC design maximizes the operational range, reducing fleet downtime for charging and optimizing routing logistics.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China E-Cargo Vehicle Motors Manufacturers and China E-Cargo Vehicle Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体