| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

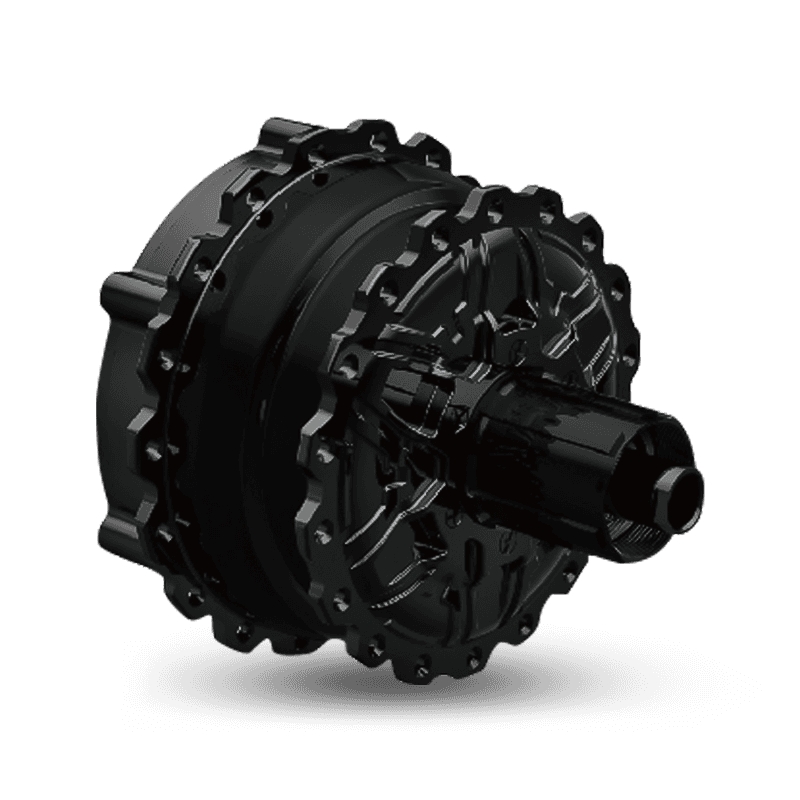

E-Karting Motors

-- Steady & Reliable Manufacturer --

Introduction

Welcome to the high-performance segment of electric propulsion with HENTACH’s E-Karting Motors. The electric karting industry demands a unique blend of instantaneous torque, high-speed capability, sustained thermal performance, and absolute reliability to deliver the thrilling, competitive experience racers expect. Our motors are not simply adapted; they are purpose-built to meet the high-stress, dynamic requirements of racing. For over three decades, HENTACH (formerly Hengtai Motor) has specialized in electric drive systems, and our E-Karting line represents the pinnacle of our engineering in power density and thermal management, primarily utilizing advanced, high-power Brushless DC (BLDC) technology.

For karting manufacturers, race teams, and track operators, the critical motor requirements center on peak power output, heat dissipation during aggressive duty cycles, and integration with sophisticated electronic speed controllers (ESCs). We utilize high-grade, rare-earth permanent magnets and meticulously optimized stator windings to maximize the motor's power and torque curves, ensuring explosive acceleration out of corners and high sustained top speeds. Crucially, the punishing nature of karting—with frequent acceleration, hard braking (which involves regenerative power spikes), and minimal airflow—makes thermal management a top priority. To combat heat saturation, we leverage our proprietary expertise in aluminum and magnesium alloy die casting to create motor housings with an optimized structure and high thermal conductivity. This superior heat dissipation ensures that the motor avoids thermal throttling and maintains consistent peak performance throughout the entire race or session. This sustained output is a key differentiator against competitors who may experience significant power fade.

HENTACH’s E-Karting Motors are designed for seamless integration into high-voltage systems (typically 48V to 96V) and are optimized to work with advanced ESCs, often including features for field-oriented control (FOC) for smooth, highly responsive power delivery. We provide customization options including specific mounting interfaces, specialized output shafts for various axle configurations (chain drive or direct drive), and robust connectors rated for high current loads. Every motor undergoes a rigorous testing regime on our dedicated high-power test benches, simulating race conditions, including sustained high-RPM operation and high current cycles, all managed under our ISO 9001 certified quality system. This commitment to extreme testing ensures that when you choose a HENTACH E-Karting Motor, you are selecting a competition-ready drive unit engineered for victory and proven for long-term reliability on the track. Our legacy of precision, combined with the extreme performance of our BLDC technology, makes us the ideal partner for high-adrenaline electric racing.

Specification

| Parameter | Range / Detail |

|---|---|

| Motor Type | High-Power Brushless DC (BLDC) |

| Rated Power | 5 kW to 30 kW (Peak) |

| Voltage Options | 48V, 72V, 96V (High Voltage Systems) |

| Peak Torque | Instantaneous, optimized for acceleration |

| Speed Range | Up to 15,000 RPM (Motor Speed) |

| Thermal Management | Optimized Die-Cast Housing, Internal Thermal Sensors |

| Commutation | Optimized for Field-Oriented Control (FOC) |

| Durability | High-Grade Bearings, Reinforced Shafts |

| Ingress Protection | IP55 Standard (Protected against dust and low-pressure water) |

Applications

Commercial Karting Tracks: Providing reliable, low-maintenance motors for rental fleets that require consistent power and durability for all-day use.

Competitive E-Kart Racing: High-output motors designed for professional and semi-professional racing leagues demanding maximum power-to-weight ratios.

Racing Simulators: Used in advanced, force-feedback racing simulators that require dynamic, high-response drive systems.

Light Electric Racing Prototypes: Customized drive units for speed record attempts or niche electric vehicle competitions.

Amusement Park Rides: High-durability motors used in powered bumper cars and other electric track-based amusement rides.

Advantages

Maximized Power Density: Delivers explosive torque and horsepower in a lightweight, compact package, essential for competitive racing.

Sustained Performance: Superior thermal design (via specialized die-casting) prevents power fade, ensuring consistent motor output from the first lap to the last.

Regenerative Braking Capability: Optimized for high-current regeneration, improving overall system efficiency and reducing wear on mechanical brakes.

High Reliability & Uptime: BLDC technology drastically reduces maintenance, providing track operators with maximum vehicle uptime and reduced running costs.

Customizable to Rules: Ability to customize winding and power output to meet specific class limitations and racing regulations while maximizing performance within those constraints.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China E-Karting Motors Manufacturers and China E-Karting Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体