| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

E-City Commuter Motors

-- Steady & Reliable Manufacturer --

The Essence of Urban Mobility: Quiet, Efficient E-City Commuter Motors

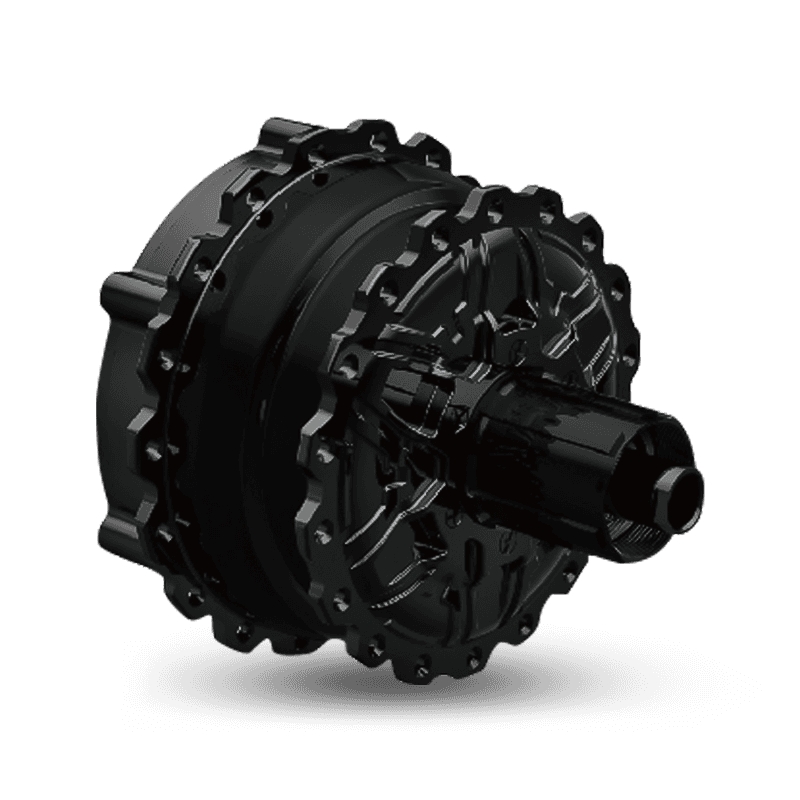

Electric city bikes are defining the future of urban transport, offering a clean, efficient, and enjoyable alternative to cars. The core requirements for the E-City Commuter Motor are fundamentally different from those of cargo or mountain bikes. The focus shifts entirely to Seamless Integration, Acoustic Silence, and Regulatory Compliance (particularly the 250W/25 km/h EPAC standard in Europe). Our city hub motors are engineered to be felt, not seen or heard, providing gentle, reliable assistance that makes daily commuting effortless and stress-free.

The aesthetic of an e-bike is a major selling point in the commuter market. Our motors boast a Slim, Low-Visual-Impact Shell designed to maintain the elegant, streamlined profile of a traditional bicycle. The lightweight construction, typically under 3.0 kg, ensures that even without power, the bicycle remains easy to pedal and maneuver—a crucial factor when walking or carrying the bike up stairs. This balance of power and portability is achieved through meticulous design, utilizing specialized planetary gear ratios that optimize efficiency at the low-to-mid speeds typical of urban travel.

Acoustic Engineering: A Focus on Quiet Operation

A loud or whining motor can quickly degrade the commuting experience. HENTACH has invested heavily in acoustic engineering to create a Low Noise Geared Hub Motor that operates at less than 55 dB—quieter than a normal conversation. This is achieved through three key measures: high-precision CNC machining of all internal components to micron-level tolerances, the use of proprietary damping materials in the motor housing, and the selection of premium, quiet-running bearings. The result is a motor that provides smooth acceleration and consistent speed maintenance without distracting noise, making the ride more pleasurable and increasing the perceived value of the final bicycle product.

Efficiency is the lifeblood of the commuter E-Bike. Commuters rely on their bikes to cover a predictable distance on a single charge. Our motors are optimized for High Coasting Efficiency. When the assistance cuts out (either at the legal speed limit or when the rider stops pedaling), the internal clutch disengages the motor core almost entirely. This virtually eliminates drag, allowing the rider to coast freely or pedal easily without power, significantly extending the battery range compared to drag-prone direct-drive or poorly designed geared systems. This range optimization is a major benefit for both the end-user and the OEM, allowing for smaller, lighter batteries without sacrificing advertised range.

Compliance, Integration, and OEM Support

For manufacturers targeting the lucrative European and regulated global markets, compliance is paramount. Our 250W City Commuter Motors are specifically engineered to meet the necessary EPAC (Electrically Power Assisted Cycles) standards. We offer complete integration support, including customized cable lengths, compatible mounting hardware for standard 100mm/135mm dropouts, and plug-and-play connections for major controller and display brands. Whether the application requires a simple speed sensor or a more sophisticated torque-sensing setup, HENTACH provides the necessary motor variant. By focusing on robustness, minimal maintenance requirements, and effortless integration, our E-City Commuter Motors provide the reliable, high-quality foundation needed for success in the competitive urban mobility market.

Key Specifications Table

| Parameter | Value/Range |

|---|---|

| Motor Type | Low Noise Geared Hub Motor |

| Rated Power (W) | 250W (EU/Global Standard) |

| Peak Torque (Nm) | 35 Nm−50 Nm |

| Voltage Compatibility | 36V DC |

| Weight (kg) | ≤2.8 kg (Ultra-Light) |

| Design Profile | Slim, Low-Visual-Impact Shell |

| Noise Level | ≤55 dB (Quieter than normal conversation) |

| Sensor Type | Speed Sensor Standard |

Primary Applications

-

Urban E-Bikes and Hybrids: Perfect for daily transportation, navigating traffic, and tackling light inclines.

-

Folding E-Bikes: Compact size and lightweight design make them ideal for folding bike applications where weight is critical.

-

Bike-Sharing Programs: Reliable and tamper-resistant motor units suitable for high-usage environments.

Key Competitive Advantages

-

Exceptional Acoustic Performance: Optimized gearing and motor shell design result in a whisper-quiet motor, enhancing the premium feel of the bicycle.

-

Standard 250W Compliance: Perfectly tailored to meet strict European EPAC regulations, ensuring quick market entry for EU clients.

-

High Coasting Efficiency: Features a robust clutch mechanism that virtually eliminates drag when pedaling without assistance, mimicking a standard bicycle ride.

-

Durability for Daily Use: While lightweight, the components are tested for daily stop-start commuting cycles, offering years of maintenance-free operation.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China E-City Commuter Motors Manufacturers and China E-City Commuter Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体