| Power | Stall Torque | Weight(KG) |

| 200-250 | 40 | 1.95(220w) |

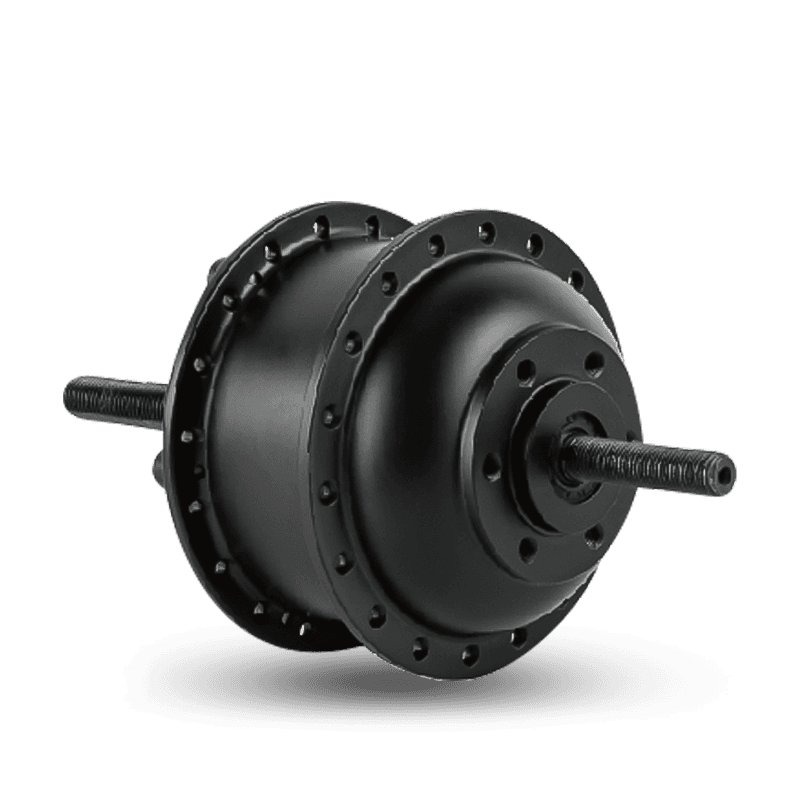

1000W Electric Vehicle Drive

-- Steady & Reliable Manufacturer --

High-Performance Propulsion: The 1000W Drive Standard

As the world transitions toward more powerful light electric vehicles (LEVs), the 1000W electric vehicle drive has emerged as the definitive solution for high-speed mopeds, cargo trikes, and performance e-bikes. This power class marks the boundary between simple pedal assistance and true motorized transport. At our manufacturing facility, which has been at the forefront of electromechanical innovation since 1995, we have developed the 1000W series to provide a "professional-grade" power profile. Formerly operating under the "Hengtai" name, our 30-year heritage has taught us that at 1000W, every component is under intense stress. From the copper windings to the axle geometry, our 9,000sqm campus is equipped to produce components that don't just reach this power level but sustain it for tens of thousands of miles.

Manufacturing a 1000W drive requires a sophisticated understanding of material science. We utilize 500-ton die-casting machines to produce motor housings from premium aluminum-magnesium alloys. These housings are not just enclosures; they are high-performance heat sinks designed to manage the significant thermal output of a 1000W motor running at high duty cycles. Our ISO 9001 certified process includes the use of high-density silicon steel and oxygen-free copper, which are precision-wound to maximize the "fill factor." This ensures that the motor delivers a smooth, linear power curve with a peak efficiency of over 85%. Whether it is used in a high-speed urban moped or a heavy-duty industrial tractor, the HENTACH 1000W drive is engineered for unwavering reliability.

Durability is the hallmark of our engineering philosophy. In a market where many 1000W motors fail within the first year due to gear fatigue or thermal burn-out, our units are built to a different standard. We famously tested our motor designs to the 50,000-mile mark, proving that with proper electromechanical engineering, electric drives can outlast the vehicles they power. This longevity is achieved through precision CNC processing of all moving parts and our proprietary micro-arc oxidation coating, which provides a level of corrosion and wear resistance that is unmatched in the industry. For the B2B client, this translates to a "fit and forget" solution that enhances the end-user's trust in the final vehicle.

Technical Drive System Parameters

| Technical Parameter | Metric / Standard | Performance Focus |

|---|---|---|

| Rated Continuous Power | 1000W (S1 Duty Cycle) | Sustained High-Speed Power |

| Peak Power Output | 1500W - 1800W | Instantaneous Acceleration |

| Operating Voltage | 48V / 60V / 72V DC | Versatile Battery Configuration |

| Torque Density | 95Nm - 110Nm | Heavy-Load Starting Torque |

| Max Efficiency | ≥ 86% | Maximum Battery Utilization |

| Magnet Grade | N42SH Neodymium | 150°C Thermal Protection |

| Phase Current Peak | 45A - 60A | High-Performance Controller Ready |

| Surface Treatment | Micro-arc Oxidation Coating | Extreme Corrosion Resistance |

| Cooling Method | Passive High-Surface Fins | Optimized for High-Speed Airflow |

| Bearing Specification | C3 High-Speed Sealed Bearings | Low Friction at High RPM |

Heavy-Duty and Performance Applications

Our 1000W drive systems are the primary choice for Electric Mopeds and High-Speed Scooters that require sustained speeds of 45-60 km/h. At these speeds, air resistance and rolling friction increase exponentially, and only a true 1000W drive can maintain performance without overheating. Furthermore, these motors are widely integrated into Heavy-Duty Cargo Trikes used for urban logistics. In these applications, the 100Nm torque output allows for the transport of 200kg+ payloads up gradients that would stall smaller motors.

- Electric Motorcycle Conversions for hobbyists and professionals.

- Industrial Material Handling Vehicles and warehouse tugs.

- Agricultural Utility ATVs for farm and vineyard transport.

- High-Performance Fat Tire E-bikes for extreme off-road racing.

- Ground Support Equipment for airports and large campuses.

Engineered for Industrial Longevity

The advantage of the HENTACH 1000W series lies in its Structural Over-Engineering. We recognize that 1000W of power can easily bend standard axles or strip standard gears. Therefore, we utilize 40Cr steel for our axles, heat-treated to an HRC of 45-50, and precision-ground on CNC machines to ensure perfect bearing alignment. This reduces internal friction and prevents the "wobble" that can lead to motor failure over time. By using our 500-ton die-casting infrastructure, we ensure that the housing itself is a structural member of the vehicle, providing rigidity and stability at high speeds.

Additionally, our Advanced Electromagnetic Simulation allows us to minimize the "cogging torque," ensuring that the vehicle feels smooth even at very low speeds—a common difficulty for high-power motors. This refinement is a direct result of our 30-year legacy in the industry. Our motors are backed by a history of durability where 50 units surpassed 50,000 miles of service. For B2B partners, this means partnering with a manufacturer that understands the complexities of high-power propulsion and has the ISO 9001 certified facilities to deliver a consistent, world-class product every time.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China 1000W Electric Vehicle Drive Manufacturers and China 1000W Electric Vehicle Drive Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体