| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

Aluminum Die Casting for E-Vehicles

-- Steady & Reliable Manufacturer --

Foundational Strength: Precision Aluminum Die Casting for E-Vehicles

The performance, durability, and thermal management of any electric vehicle motor hinge critically on the quality and design of its metal housing. At HENTACH, our focus on Aluminum Die Casting for E-Vehicles is one of our core competitive advantages, enabling us to produce motor shells and structural components with unparalleled strength-to-weight ratios, intricate internal geometries for optimal heat dissipation, and precise dimensional accuracy. By managing the entire high-pressure die casting (HPDC) process in-house, we maintain strict control over material purity, eliminate common defects like porosity, and ensure rapid prototyping and customization of proprietary motor housings for our OEM clients.

Superior Materials for Thermal Efficiency and Durability

The aluminum alloys we use, such as A380 or similar high-strength variants, are chosen specifically for their exceptional thermal conductivity and corrosion resistance. These properties are crucial because the motor shell serves as the primary heat sink, transferring heat away from the motor’s windings and electronics. Our engineers utilize advanced computational fluid dynamics (CFD) simulations to design molds that maximize thin-walled surface area, strategically integrating cooling fins to ensure effective heat transfer. This specialized thermal design prevents thermal throttling, maintaining peak motor performance even during continuous, high-load operation, which is essential for the demanding environments in which electric vehicles operate.

In-House Precision and Customization

By controlling the casting process in-house, we guarantee dimensional accuracy to within ±0.1 mm tolerance—a critical factor in the seamless assembly of internal motor components like the stator, rotor, and bearings. This precision minimizes air gaps, reducing friction and vibration, and ensuring the motor operates with smooth, quiet performance. For our custom Ebike and E-Moped partners, we offer specialized bespoke casting services, creating unique molds and tooling that can incorporate features like custom mounting flanges, branding logos, and specialized axle interfaces directly into the motor housing. This eliminates the need for costly post-casting welding or modifications, enhancing both the structural integrity and IP protection for our clients' designs.

High-Pressure Die Casting for Strength and Performance

Our HPDC technology forces molten aluminum into steel molds under extreme pressure and speed, producing dense, thin-walled parts with superior surface finish and mechanical strength. These attributes are critical for motor components, which must withstand significant impact and structural stress during vehicle operation. The result is a robust, highly durable motor housing that is capable of enduring the rigors of day-to-day use, especially in high-speed and heavy-load applications.

Comprehensive Quality Control

The in-house control of the casting process ensures exceptional quality control at every stage, from material selection and mold design to final production. We inspect every batch of castings for any potential defects, ensuring that each motor housing meets our high standards for structural integrity and thermal efficiency.

By leveraging state-of-the-art die casting technology, HENTACH’s Aluminum Die Castings provide a solid foundation for all of our electric motors. These meticulously engineered housings not only offer outstanding thermal management and mechanical strength, but also form the basis for market-leading durability and performance that our clients depend on. From prototype to mass production, we deliver precision-crafted solutions that set the standard in the industry.

Technical Specifications and Process Control

The technical specification of our die-casting process is defined by strict adherence to metallurgy, pressure control, and dimensional precision. The data below outlines the key parameters that govern the quality and performance of our aluminum motor housings. This is followed by a detailed description of the specialized casting controls and post-processing steps that ensure the final component meets the rigorous demands of electric vehicle structural and thermal performance, providing critical assurance to B2B clients.

| Parameter | Value/Rating |

|---|---|

| Casting Method | High-Pressure Die Casting (HPDC) |

| Primary Alloy Used | Aluminum A380 (High-Strength, High Thermal Conductivity) |

| Dimensional Tolerance | ±0.1 mm (On Critical Dimensions) |

| Casting Purity Control | Spectrometer Analysis (Batch-to-Batch Consistency) |

| Casting Feature | Integrated Cooling Fins and Internal Ribbing |

| Post-Casting Process | Precision T6 Heat Treatment (For High Strength) |

| Surface Finish | As-Cast Finish, Ready for Powder Coating |

| Porosity Control | Real-Time Monitoring and X-Ray Spot Checks |

The use of High-Pressure Die Casting (HPDC) is essential for achieving the complex, thin-walled structures required for optimal thermal transfer in motor housings. We maintain precise control over the alloy's chemical composition using an in-house spectrometer analysis for every molten batch, ensuring material consistency and eliminating impurities that lead to weaknesses or porosity. Porosity control is managed through highly efficient venting in the mold design and is validated via periodic X-Ray spot checks on critical load-bearing parts, guaranteeing the structural integrity of the housing against impact and fatigue. For components requiring maximum tensile strength, a T6 heat treatment process is applied post-casting. This process strengthens the aluminum crystalline structure, which is vital for axles and mounting flanges that bear the vehicle's full weight and stress. The final die-cast component is dimensionally checked using high-precision CMM (Coordinate Measuring Machine) equipment, ensuring the tight tolerances required for bearing seats and stator mounting surfaces are met perfectly before proceeding to final motor assembly. This detailed control over the casting phase is the backbone of HENTACH's motor reliability and high-durability guarantee.

Applications and Structural Component Manufacturing

Our expertise in Aluminum Die Casting is leveraged across numerous electric vehicle and structural component applications, providing lightweight, high-strength solutions that are foundational to modern e-mobility design. The ability to cast complex, near-net shapes with precision offers significant design flexibility and cost reduction compared to alternative manufacturing methods like billet machining or sand casting. We focus on producing components that serve both thermal and structural functions simultaneously across the EV spectrum.

-

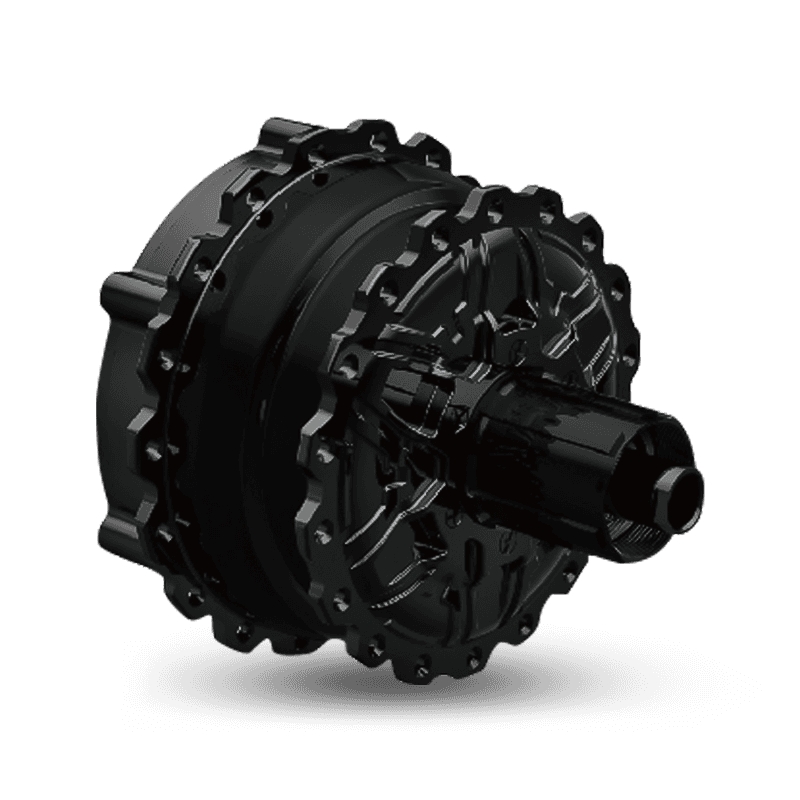

Hub Motor Shells (Outer Rotors): The main application, where the casting forms the wheel rim interface, the structural housing, and the primary heat sink, demanding high precision and excellent thermal properties.

-

Controller Housings and Inverter Cases: Die casting provides sealed, thermally efficient enclosures for heat-sensitive power electronics, often with complex internal ribbing and external cooling fins cast directly into the design.

-

Battery Pack Enclosures: Used for creating lightweight, sealed, and flame-resistant structural trays and lids for EV battery packs, providing the necessary thermal pathway for internal cooling systems.

-

Gearbox and Transaxle Casings: Structural housings for high-torque gearbox motors and transaxles (e.g., in golf carts or AGVs), requiring high dimensional accuracy to ensure perfect alignment of gear shafts and bearings under heavy load.

By integrating die casting early into the design process, we enable OEM partners to consolidate multiple components into a single, high-integrity casting, drastically reducing assembly time, minimizing potential leak paths (for sealed units), and lowering the overall weight of the drive system. This in-house capability for producing thermally optimized and structurally sound aluminum components is a decisive enabler for high-performance and long-life electric vehicle designs across all target markets.

Advantages of In-House Die Casting Control

Controlling the Aluminum Die Casting process internally, rather than relying on third-party suppliers, provides HENTACH and our OEM partners with significant, measurable advantages in terms of quality, cost, and time-to-market. These benefits stem directly from our ability to integrate metallurgical, thermal, and structural design disciplines at the earliest stages of motor development.

-

Superior Thermal Performance: Direct control over the casting process allows us to optimize the internal and external geometries for heat dissipation, ensuring the most efficient thermal path and minimizing the motor's operating temperature during continuous duty.

-

Exceptional Dimensional Accuracy: In-house quality checks (CMM, X-Ray) ensure critical tolerances (±0.1 mm) for bearing seats and stator mounting are met perfectly, eliminating assembly issues and guaranteeing quiet, vibration-free motor operation.

-

Rapid Customization and Prototyping: We can rapidly modify and create new tooling to incorporate custom mounting flanges, unique aesthetics, or specialized cooling features into the motor shell design, dramatically shortening the prototype phase for custom motor development projects.

-

Zero Porosity and High Structural Integrity: HPDC and strict material purity control eliminate internal voids (porosity), making the housing stronger, more fatigue-resistant, and ideal for components requiring high-integrity sealing (IP66/IP67).

-

Reduced Component Cost and Lead Time: By cutting out the complexity and margin of a third-party casting supplier, we reduce the component's unit cost and gain direct control over the casting production schedule, ensuring stable supply and shorter lead times for mass production.

-

Consolidated Component Design: Die casting allows complex features (e.g., cable routing channels, mounting inserts) to be integrated into a single component, reducing the total parts count in the Bill of Materials (BOM) and simplifying vehicle assembly.

This foundational manufacturing capability underpins the quality and performance guarantee across our entire electric drive unit portfolio, securing a clear competitive advantage for our OEM clients in structural and thermal reliability.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Aluminum Die Casting for E-Vehicles Manufacturers and China Aluminum Die Casting for E-Vehicles Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体