| Power | Stall Torque | Weight(KG) |

| 350-750 | 90 | 4.2 |

A380 Aluminum Die Casting

-- Steady & Reliable Manufacturer --

Introduction

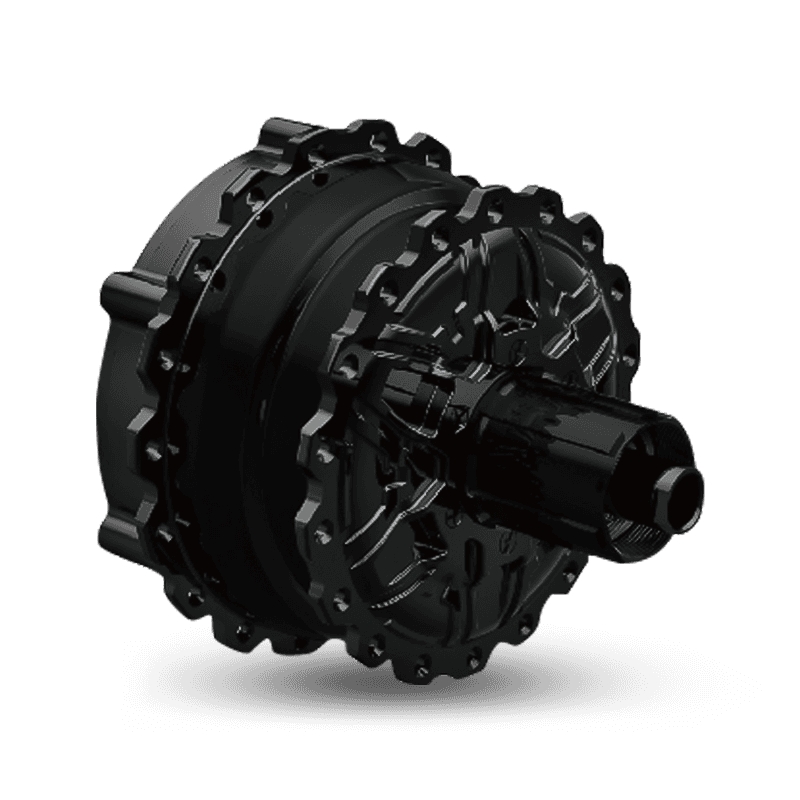

A380 Aluminum Die Casting is the cornerstone of HENTACH's metal component manufacturing, providing the high-quality, lightweight, and complex structural parts essential for modern DC motor assemblies and drive systems. A380 is a highly versatile and widely used aluminum alloy in the die casting industry, prized for its excellent balance of mechanical strength, fluidity, heat resistance, and cost-effectiveness. For over three decades, HENTACH (formerly Hengtai Motor) has utilized this alloy in its vertically integrated manufacturing process, allowing us to produce the robust, rigid, and thermally optimized enclosures that protect and enhance our motors. This in-house casting capability is a significant competitive advantage, ensuring complete control over material quality, dimensional consistency, and the rapid prototyping of complex geometries.

For B2B buyers—including electric vehicle manufacturers, industrial machinery builders, and power tool companies—the critical advantages of A380 die casting lie in its superior heat dissipation, structural rigidity, and economical production scale. Heat Dissipation is a core motor requirement; A380's high thermal conductivity allows us to design motor housings and heat sinks with optimized cooling fins that quickly draw heat away from the motor's core, preserving the integrity of the magnets and windings. Structural Rigidity is necessary to hold the motor's internal components (bearings, shafts, stators) in precise alignment, especially under load and vibration. Our high-pressure die casting process, executed on our 500-ton machines, produces motor housings with minimal porosity and exceptional dimensional stability. Economical Production Scale is key to high-volume applications; A380's excellent flow characteristics allow us to rapidly cast complex "near-net shape" parts, minimizing the need for extensive subsequent High Precision Machined Parts operations and reducing the overall unit cost. HENTACH's mastery of the A380 alloy ensures that the final casting is free of critical defects like cold shuts or high porosity, which would otherwise compromise the part's integrity.

Our in-house die casting services are governed by our ISO 9001 certified quality system. We perform routine testing of the molten alloy composition (spectrometry) and utilize techniques like X-ray inspection to verify internal soundness and low porosity. Once cast, all critical mating and bearing surfaces are finished using our CNC machining centers to achieve the required precision and surface finish. This vertical integration—from raw material alloy to final precision-machined housing—guarantees a stable supply chain, superior quality control, and the fastest possible turnaround for custom Motor Housing Die Casting designs. We also offer customization of the surface finish, including powder coating, plating, and anodizing, to enhance corrosion resistance for outdoor or demanding environments.

Specification

| Parameter | Range / Detail |

|---|---|

| Alloy Type | A380 Aluminum Alloy (ASTM Standard) |

| Process | High-Pressure Cold Chamber Die Casting |

| Casting Equipment | Modern, High-Tonnage Die Casting Machines (e.g., 500 Ton) |

| Key Properties | Excellent Strength, Heat Dissipation, and Casting Fluidity |

| Application Focus | Motor Housings, Gearbox Casings, Structural Mounts, Heat Sinks |

| Quality Control | Spectrometry for Material Verification, X-Ray Inspection for Porosity |

| Finishing | CNC Machining of Critical Surfaces and Finishing/Coating Options |

| Advantages Over Steel | Significant Weight Reduction, Superior Thermal Conductivity |

| Tolerance | As-Cast Dimensional Tolerances Follow Industry Standards (DMT), Tight Machined Tolerances Follow Client Spec |

Applications

Electric Vehicle Motors: Housings and end caps for traction and auxiliary motors, maximizing heat dissipation and reducing weight.

Industrial Gearboxes: Rigid casings for planetary and worm gear reduction systems, ensuring gear alignment under heavy load.

Power Tool Housings: Providing lightweight, durable, and complex enclosures for battery-powered electric tools.

Electronic/LED Enclosures: Used as high-performance heat sinks and protective enclosures for power electronics and lighting systems.

Medical Equipment Frames: Structural components requiring a lightweight, rigid, and durable material.

Advantages

Exceptional Heat Dissipation: High thermal conductivity of A380 alloy prevents motor overheating, preserving performance and magnet integrity.

Cost-Effective for Volume: Rapid casting cycles and the ability to produce "near-net shape" complex parts make it ideal for high-volume, economical production.

Excellent Strength-to-Weight Ratio: Provides the necessary structural rigidity to house precision components while significantly reducing the overall weight compared to steel or cast iron.

Precision and Consistency: In-house capability ensures tight control over dimensional consistency, a prerequisite for subsequent precision machining.

Versatile Finish Options: Easily accepts various surface treatments (powder coating, anodizing) to meet aesthetic or corrosion resistance needs.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China A380 Aluminum Die Casting Manufacturers and China A380 Aluminum Die Casting Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体