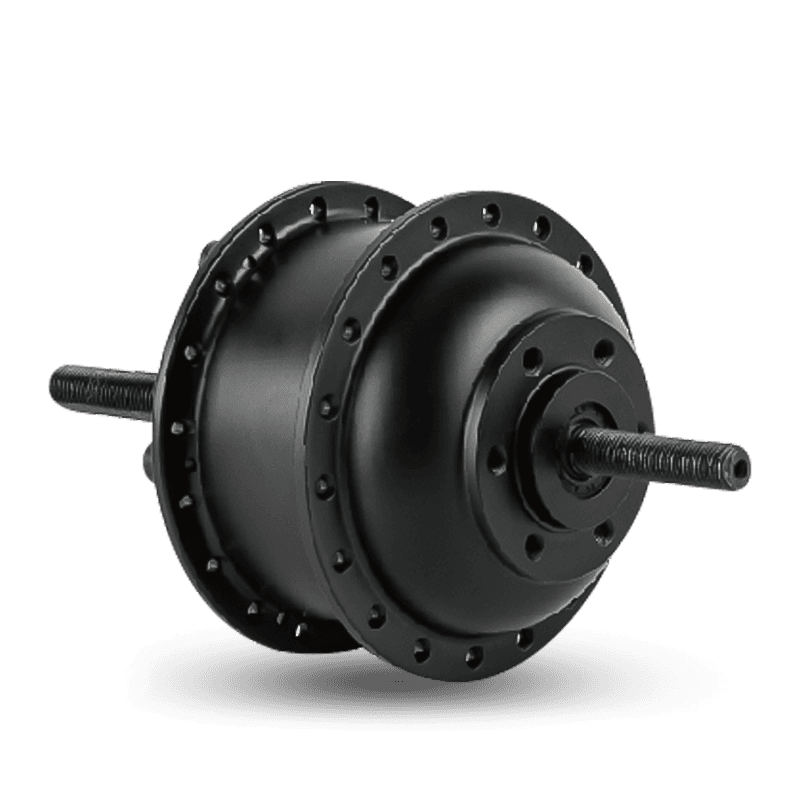

| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

Plastic-Steel Gear Hub Motor Technology

-- Steady & Reliable Manufacturer --

Introduction to Patented Gear Technology

Our proprietary **Plastic-Steel Gear Hub Motor Technology** addresses the critical weakness in many geared hub motors: the plastic gear train. By blending specialized engineering plastics with steel components in a unique, patented structure, we have created gears that offer the silence and shock absorption of nylon while delivering the **load capacity and longevity approaching all-steel gears.** This innovation is central to our reputation for reliability.

Comparative Specifications

| Feature | Hentach Plastic-Steel Gear | Standard Nylon Gear |

|---|---|---|

| Service Life (Tested) | ≥ 40,000 km | ~ 15,000 km |

| Noise Profile | Low/Silent | Low/Silent |

| Peak Torque Load | High | Medium |

| Temperature Tolerance | Excellent | Good |

| Shock Resistance | Superior | Good |

| Failure Mode | Gradual Wear | Sudden Shearing |

Applicability of Technology

- E-Commuter Fleets: Where consistency and low maintenance are mandatory for operational efficiency.

- Shared E-Scooters/Bikes: Surviving the high stresses and constant usage cycles of sharing platforms.

- E-Fat Bikes: Handling the high current draw and shock loads when riding off-road or in sand/snow.

- Industrial/Specialty Vehicles: Applications requiring sustained high-torque output without premature gear failure.

Technology Advantages

-

Exceptional Durability: Drastically reduces the chance of gear stripping, a common point of failure in standard motors.

-

Reduced Maintenance Costs: The long-life gears lower the total cost of ownership (TCO) for manufacturers and fleet operators.

-

Noise Reduction: Maintains the quiet operation profile of geared motors, essential for city commuting.

-

Weight Optimization: Provides steel-like strength at a reduced weight compared to a full-steel gear set, contributing to overall bike efficiency.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Plastic-Steel Gear Hub Motor Technology Manufacturers and China Plastic-Steel Gear Hub Motor Technology Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体