| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

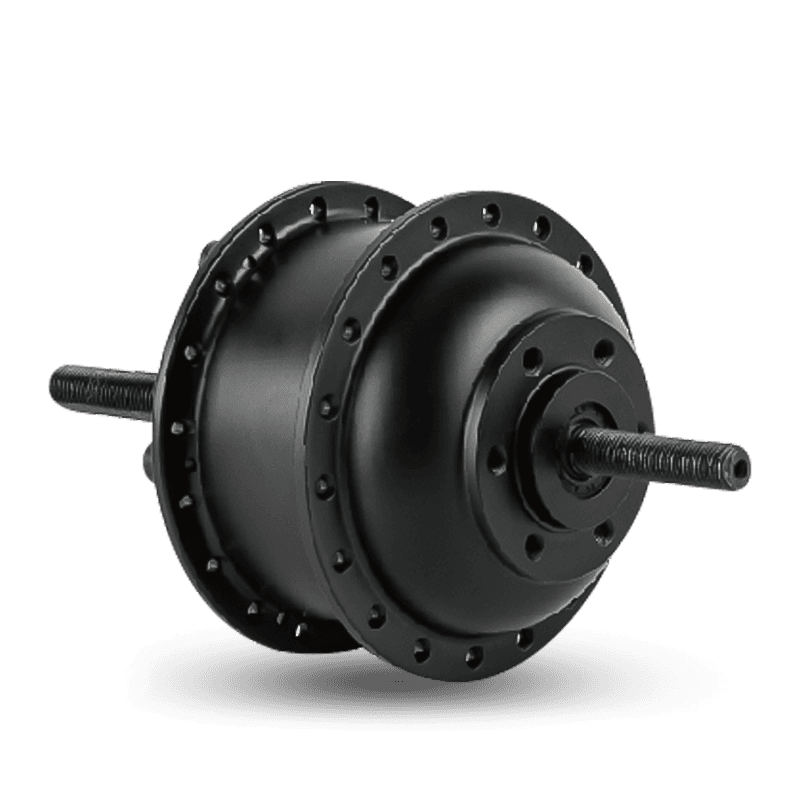

Geared Hub Motor Technology

-- Steady & Reliable Manufacturer --

Revolutionizing Torque: The Science of Geared Hub Motors

In the world of electric mobility, the quest for the perfect balance between size, weight, and torque has led to the peak of geared hub motor technology. As a premier manufacturer with over 30 years of electromechanical innovation, our company—formerly known globally as Hengtai Motor—has spent decades perfecting internal reduction systems. Unlike direct-drive motors, geared motors utilize an internal planetary gear set to allow the motor to spin at a much higher, more efficient RPM while delivering substantial torque to the wheel. This mechanical advantage is what allows a compact 2kg motor to outperform much larger units during uphill climbs. Our 9,000-square-meter campus houses the specialized equipment necessary to produce these high-tolerance components, ensuring that every geared unit we ship meets the rigorous ISO 9001 quality control standards that have defined our brand since 1995.

The secret to a superior geared motor lies in the materials of the planetary system. Most competitors rely solely on plastic gears, which often fail under thermal stress. At HENTACH, we utilize our Patented Nylon-Steel Gear technology. By combining the natural vibration-damping and noise-reduction properties of high-grade nylon with the structural reinforcement of high-tensile steel, we have solved the industry's most common failure point. This innovation ensures that our geared hub motors can handle high-torque startups without stripping teeth, a claim we backed with a historical 30,000-mile durability guarantee. In fact, real-world testing saw many of our units exceeding 50,000 miles of operation. Our 500-ton die-casting machines allow us to create a precision-engineered aluminum-magnesium alloy shell that protects these gears while providing the thermal conductivity needed to dissipate heat during heavy use.

Beyond the gears themselves, our technology focuses on the integration of the freewheel and clutch systems. A high-quality geared hub motor must offer zero drag when the motor is off, allowing the rider to pedal the e-bike like a traditional bicycle. Our internal one-way clutches are manufactured using precision CNC machine tools to ensure smooth engagement and disengagement. This level of electromechanical synergy is the result of 30 years of "Hengtai" heritage combined with modern "HENTACH" engineering. For B2B partners, this technology translates into lower warranty claims, higher customer satisfaction, and a product that stands out in the crowded electric bicycle market. We continue to push the boundaries of what is possible in geared propulsion, ensuring our clients receive the most reliable solutions available today.

Detailed Mechanical and Electrical Parameters

| Parameter Group | Feature Details | Value / Standard |

|---|---|---|

| Gear System | Planetary Reduction Set | 1:4.4 / 1:5.0 Ratios |

| Gear Material | Proprietary Nylon-Steel Hybrid | Patented Wear Resistance |

| Clutch Type | High-Precision One-Way Clutch | Zero-Drag Freewheeling |

| Rated Power Range | 250W - 750W | Optimized for EU/US Standards |

| Peak Torque | 45Nm - 80Nm | High-Torque Density Design |

| Housing Material | ADC12 Aluminum-Magnesium Alloy | Die-Cast by 500-Ton Press |

| Bearing Configuration | Sealed Deep Groove Ball Bearings | Low Friction / Long Life |

| Noise Coefficient | Under 50 Decibels | Silent Planetary Operation |

| Efficiency Curve | Peak Efficiency > 82% | Wide Range Efficiency Range |

| Thermal Protection | Internal Thermistor (optional) | 10K NTC for Motor Safety |

Commercial and Recreational Applications

Geared hub technology is the primary choice for Urban Commuter E-bikes where lightweight design is a priority. Because these motors are significantly smaller than gearless alternatives, they allow for sleeker bicycle designs that don't immediately look like "electric" vehicles. This aesthetic advantage is critical for the premium commuter market. Additionally, the high torque-to-weight ratio makes them indispensable for Folding Electric Bikes, where every gram saved counts toward the portability of the final product.

- Electric Mountain Bikes (eMTB) requiring high torque for steep trails.

- Lightweight Cargo Bikes for urban delivery and courier services.

- Trekking and Touring Bikes for long-distance reliability.

- Shared Mobility Fleets seeking low-maintenance drive units.

- Compact Electric Scooters with high climbing requirements.

The HENTACH Manufacturing Edge

The primary advantage of our geared hub motors is their Unmatched Reliability. By manufacturing the aluminum-magnesium alloy housings in-house using our 500-ton die-casting machines, we ensure a pore-free structure that perfectly aligns the internal planetary gears. Misalignment is the leading cause of gear wear; our precision CNC processing eliminates this risk at the source. Furthermore, our proprietary micro-arc oxidation coating on internal surfaces prevents the "sweating" and corrosion often found in cheaper hub motors used in humid climates.

Furthermore, our Patented Nylon-Steel Gears provide a unique selling proposition for our B2B clients. You can market a vehicle that is significantly quieter than competitors using all-steel gears, yet far more durable than those using all-nylon gears. This "best of both worlds" scenario is the result of our 30-year legacy of electromechanical innovation. When you partner with us, you are leveraging a supply chain that has successfully delivered motors exceeding 50,000 miles of real-world use, supported by an ISO 9001 certified facility that prioritizes long-term durability over short-term savings.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Geared Hub Motor Technology Manufacturers and China Geared Hub Motor Technology Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体