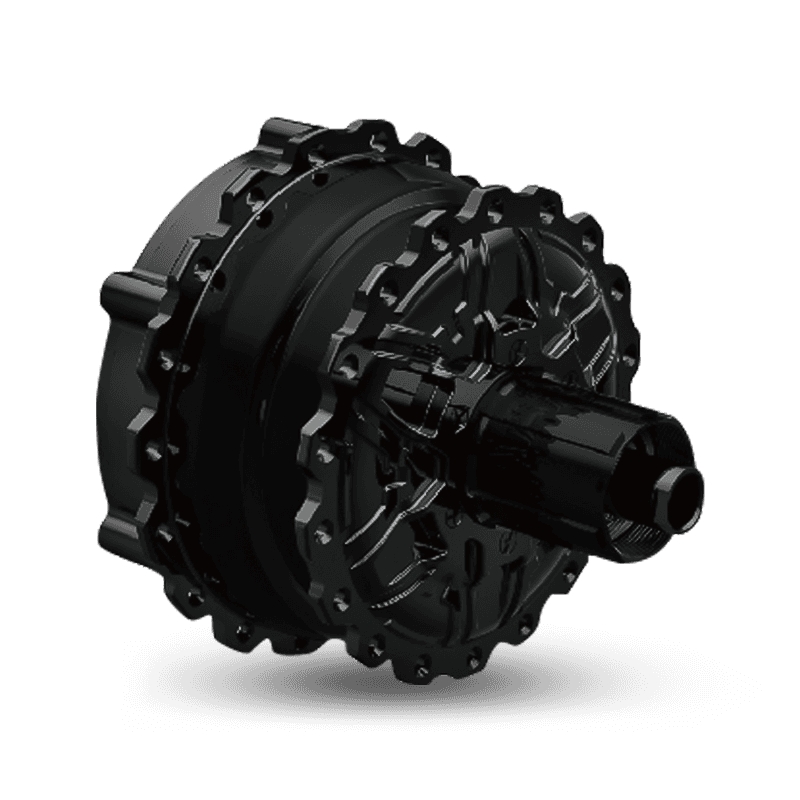

| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

Front Hub Motors for E-Bikes

-- Steady & Reliable Manufacturer --

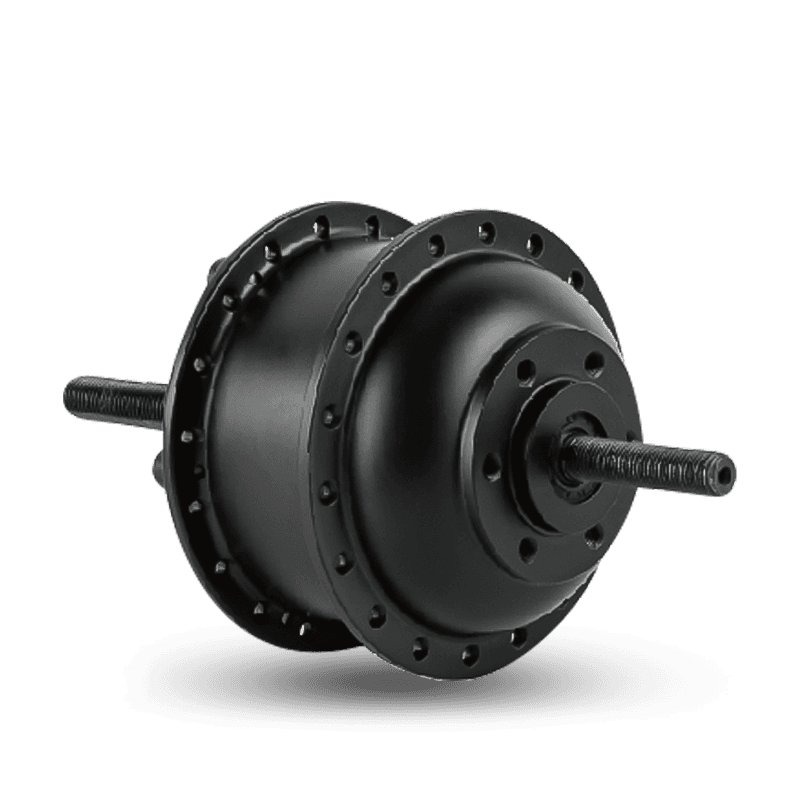

The Versatile Power of Front Hub Motors for E-Bikes

The Front Hub Motor offers a compelling combination of simplicity, cost-effectiveness, and compatibility, making it the ideal solution for conversion kits, entry-level e-bikes, and applications requiring a secondary drive system. By placing the motor in the front wheel, manufacturers can preserve the original bicycle's drivetrain (crankset, cassette, rear wheel), dramatically simplifying manufacturing and inventory management. Ningbo Yinzhou HENTACH Electromechanical is a leading supplier of front hub motors, focusing on compact design, reliable mounting, and providing a stable, intuitive power output that appeals to a broad consumer base.

The primary engineering advantage of the front motor is its plug-and-play simplicity. It allows manufacturers to maintain the standard bottom bracket shell and chainstays, enabling the integration of various drivetrain components that might be incompatible with mid-drive or rear hub motors. This configuration also allows for a "dual drive" system when paired with a mid-drive unit, though its most common use is as a standalone, lightweight, and discreet solution. Our designs prioritize a narrow hub profile to fit standard 100mm fork dropouts without modification, making it a favorite for bicycle brands looking for minimal structural changes to existing models.

Handling and Safety in Front Drive Systems

A common concern with front-drive is handling, particularly traction in loose terrain. Our R&D team has addressed this by fine-tuning the motor's power curve and integration with advanced controllers. The power delivery is governed to be smooth and progressive, preventing sudden, high-torque bursts that could cause wheel spin. Furthermore, our motor shells are constructed from high-quality, cold-forged aluminum alloy, specifically designed to withstand the unique lateral and torsional stresses placed on the front wheel and fork. Crucially, we focus on secure axle mounting solutions, offering anti-rotation washers and high-strength axles to ensure the motor remains safely locked in place, even under high torque and stress.

We offer both geared and direct-drive front motor variants to suit different OEM needs. Geared front motors are lighter and offer higher torque at low speeds, making them excellent for commuter and city bikes where quick acceleration is needed. Direct-drive front motors, while slightly heavier, are maintenance-free, silent, and offer regenerative braking capability, which is a key selling point for energy recovery and extended brake pad life in high-mileage fleet applications. As a B2B partner, HENTACH provides flexibility in choosing the best motor type for the target application. We ensure all front hub motors are compatible with both mechanical and hydraulic disc brake systems, as well as V-brakes, offering maximum market versatility. Our quality control processes, including non-destructive testing (NDT) of the axle and housing integrity, guarantee that every front motor leaves the factory ready for reliable, mass-market deployment.

Choosing our front hub motor solutions allows OEMs to rapidly develop new entry-level and conversion products. The system is inherently simpler to cable and install than mid-drives, significantly lowering the complexity and cost of the final bicycle assembly. This simplicity, combined with our competitive B2B pricing and robust warranty support, makes HENTACH the preferred manufacturer for scalable, high-volume e-bike production focused on urban accessibility and convenience.

Key Specifications Table

| Parameter | Value/Range |

|---|---|

| Motor Type | Geared or Direct Drive Hub |

| Rated Power (W) | 200W - 350W |

| Peak Torque (Nm) | $30 \text{ Nm} - 45 \text{ Nm}$ |

| Voltage Compatibility | 36V DC |

| O.L.D. Standard | 100mm (Standard Fork Dropout) |

| Axle Material | High-Strength Cr-Mo Steel |

| Brake Interface | Disc Brake Ready & Rim Brake Compatible |

| Weight (Geared) | $2.0 \text{ kg} - 2.8 \text{ kg}$ |

Primary Applications

-

E-Bike Conversion Kits: Simple installation without modifying the rear drivetrain.

-

Entry-Level City E-Bikes: Cost-effective solution for providing reliable pedal assistance.

-

Shared/Rental E-Bike Fleets: Robust, easy-to-maintain drive units.

Key Competitive Advantages

-

Minimal Frame Impact: Fits standard 100mm dropouts, preserving frame design integrity.

-

Axle Integrity: Reinforced axle with robust anti-rotation features for enhanced safety.

-

Dual Braking Compatibility: Supports both disc and rim brakes, offering flexibility for low-cost builds.

-

Ease of Assembly: Reduced complexity allows for faster and more cost-effective production line integration.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Front Hub Motors for E-Bikes Manufacturers and China Front Hub Motors for E-Bikes Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体