| Power | Stall Torque | Weight(KG) |

| 250-500 | 75 | 4.2 |

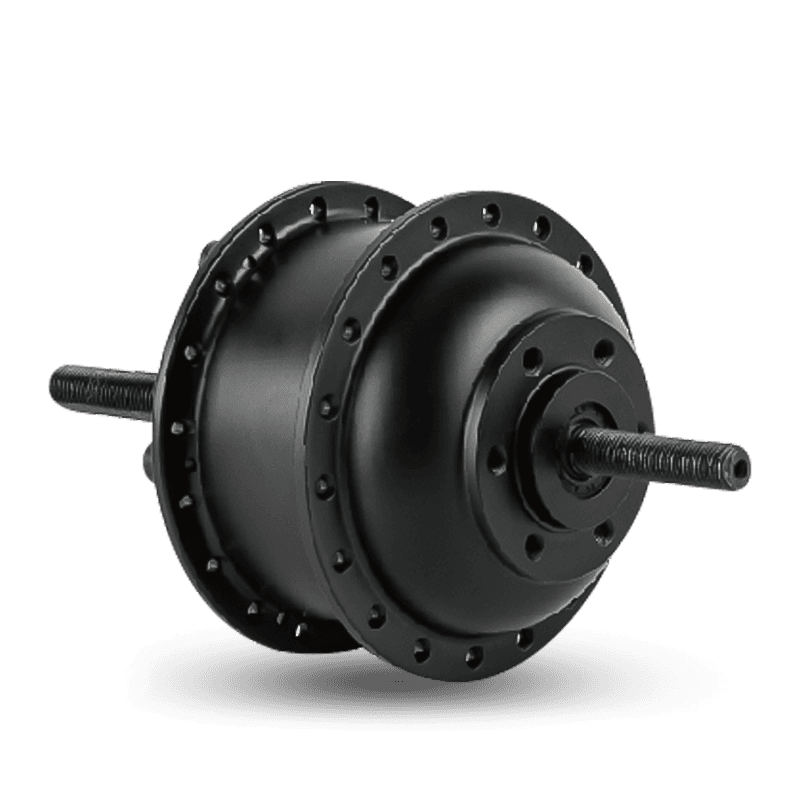

Thru-Axle Hub Motors

-- Steady & Reliable Manufacturer --

The Modern Standard: High-Security Thru-Axle Hub Motors

The bicycle industry has rapidly adopted the thru-axle standard for its superior stiffness, enhanced safety, and precise wheel alignment, particularly in performance e-bikes, eMTBs, and high-end commuter models. Our Thru-Axle Hub Motors are a direct response to this evolution, designed to integrate flawlessly with modern frame and fork standards that utilize a bolt-through design instead of traditional quick-release skewers. This technology provides a significantly more secure and robust connection, crucial for handling the increased torque and speeds associated with electric assistance.

The critical engineering challenge in adapting a hub motor to a thru-axle is maintaining the structural integrity and precision of the motor axle assembly while accommodating various thru-axle diameters (e.g., 12mm, 15mm) and thread pitches. HENTACH solves this by utilizing a fixed inner axle, precision-machined from robust alloy steel, which is internally threaded or designed with specific end caps to allow the external thru-axle to pass through and clamp the wheel securely to the frame/fork dropouts. This results in a system that is incredibly strong, virtually eliminating the risk of axle slippage or dropout damage under extreme load, a common safety concern with high-power quick-release setups.

Enhanced Performance and Frame Stiffness

The stiffness provided by the thru-axle greatly benefits the overall e-bike performance. In rear-wheel applications, the increased stiffness minimizes flex in the swingarm area, leading to more direct power transfer and better handling, especially when cornering or climbing. For front thru-axle motors, it enhances steering precision and reduces brake rotor rub, which is vital for e-bikes utilizing high-performance hydraulic disc brakes. Our thru-axle motor design is optimized for this rigidity, ensuring that the motor's power is delivered efficiently without compromising the bike's dynamic characteristics.

These motors are overwhelmingly favored for use in high-end applications, including performance eMTBs, high-speed cargo bikes, and premium touring bikes—any application where structural integrity and maximum safety are paramount. We work closely with OEM partners to supply the exact drop-out widths (O.L.D.) and axle specifications required for their frame designs (e.g., 148mm Boost for eMTBs, or specialized widths for custom cargo frames). This customization includes the development of specific aluminum end caps (torque arms) that ensure perfect alignment and provide the necessary surface contact for safe, high-torque operation. Our B2B partnership includes engineering consultation to help clients select the precise motor winding and gear ratio that, when combined with the thru-axle rigidity, delivers the optimal power and speed profile for their intended market. By adopting HENTACH thru-axle hub motors, manufacturers are investing in a future-proof, high-performance drive system that meets the highest standards of safety and riding dynamics in the modern bicycle industry.

Key Specifications Table

| Parameter | Value/Range |

|---|---|

| Motor Type | Geared Hub Motor (High-Torque) |

| Rated Power (W) | 500W - 1000W |

| Peak Torque (Nm) | $\ge 75 \text{ Nm}$ |

| Voltage Compatibility | 48V / 52V DC |

| Axle Compatibility | 12mm or 15mm Thru-Axle |

| O.L.D. Standard | 142mm, 148mm (Boost), 170mm+ (Cargo) |

| Hub Standard | Cassette Freehub Compatible |

| Primary Material | Forged Alloy Steel / CNC Aluminum |

Primary Applications

-

High-Performance eMTBs: Utilizing Boost spacing (148mm) for increased stiffness and climbing torque.

-

Heavy-Duty E-Cargo Bikes: Requires maximum axle security for high payload transport.

-

Premium E-Touring Bikes: Delivering safety and stability for high-mileage journeys over varied terrain.

Key Competitive Advantages

-

Maximum Safety & Security: Thru-axle design eliminates the risk of axle movement under high torque or impact.

-

Superior Stiff Connection: Improves frame/fork rigidity, enhancing handling and power transfer efficiency.

-

Precision Alignment: Ensures consistent disc brake rotor and cassette alignment, simplifying wheel swaps and maintenance.

-

Versatile Dropout Spacing: Available in multiple O.L.D. options (142, 148, 170+) to suit modern standards.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Thru-Axle Hub Motors Manufacturers and China Thru-Axle Hub Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体