| Power | Stall Torque | Weight(KG) |

| 180-250 | 40 | 2.18(220w) |

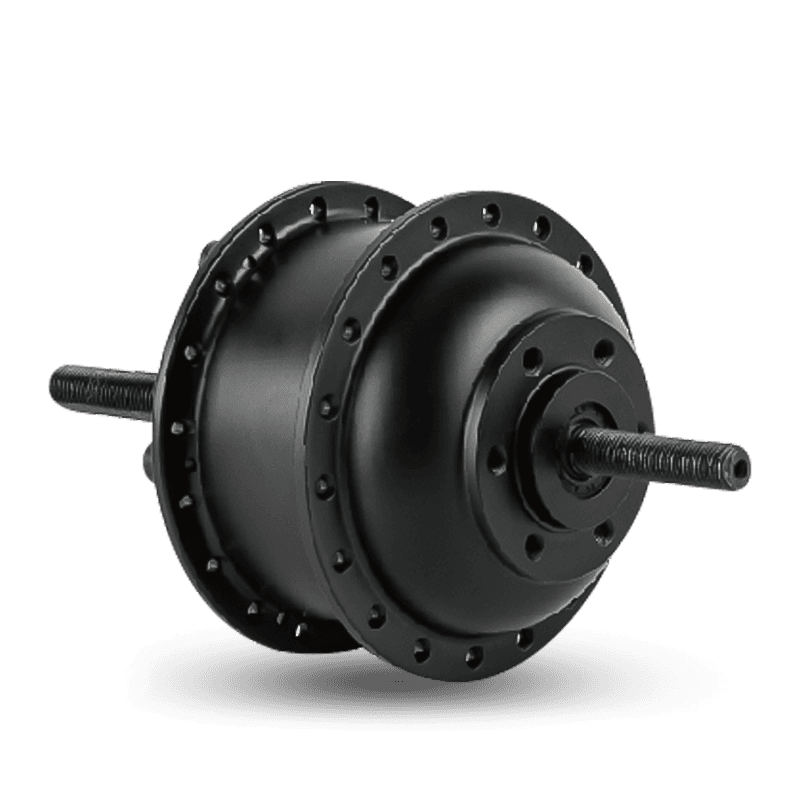

Rear Cassette Hub Motors

-- Steady & Reliable Manufacturer --

Optimal Integration and Performance: Rear Cassette Hub Motors

The Rear Cassette Hub Motor represents the most popular and versatile category in the electric bicycle drive market, seamlessly blending electric power with the traditional cycling experience. Unlike fixed-gear or freewheel systems, cassette compatibility allows riders to utilize modern multi-speed groupsets (7-speed up to 12-speed), which is non-negotiable for serious cyclists and manufacturers aiming for a premium, high-functionality product. At Ningbo Yinzhou HENTACH Electromechanical, our rear cassette motors are meticulously engineered to maximize power transmission efficiency while minimizing motor profile, ensuring easy integration into standard frame geometries.

The fundamental advantage of the rear hub motor is its ability to deliver power directly to the drive wheel, bypassing the chain and derailleur system, which simplifies installation and reduces wear on the bike's mechanical drivetrain. Our engineering focus on rear cassette models includes specialized acoustic dampening technology, utilizing high-precision planetary gears and advanced plastic-steel composites. This ensures that the motor operates at peak efficiency (often $\ge 85\%$) while producing a whisper-quiet sound profile—a critical feature for commuter and touring e-bikes. The motors are designed with optimized magnet arrangements to minimize cogging torque, providing a natural, drag-free feel when pedaling without assistance or exceeding the speed limit.

The Cassette Challenge: Strength and Reliability

One of the technical challenges in rear hub motors is integrating the cassette freehub body securely and reliably within the motor housing. Our solution involves high-strength forged aluminum construction for the freehub body, ensuring compatibility with the high forces generated by modern bicycle drivetrains, especially under heavy pedaling or aggressive shifting. The motor shell is robust yet lightweight, produced via high-pressure die casting, offering excellent thermal management to dissipate heat generated during sustained uphill climbs or high-wattage operation. We offer compatibility with various Over-Locknut Dimensions (O.L.D.), typically 135mm or 142mm, to accommodate the wide range of current frame designs used by our global OEM partners.

Our R&D team provides extensive customization for B2B clients. This includes tailoring the internal winding (T-number) to achieve specific performance outcomes—for instance, a lower T-number winding for higher speed (Class 3 speed pedelecs) or a higher T-number winding for maximum torque (ideal for touring bikes carrying luggage). We also integrate high-reliability sensors (both speed and temperature) that are sealed against environmental ingress, ensuring that the electronic control unit (ECU) receives accurate data for smooth, safe, and efficient power delivery. The versatility of the rear cassette hub motor makes it the go-to choice for manufacturers building premium commuter, touring, and trekking e-bikes globally. Partnering with HENTACH guarantees a drive system that meets the dual demands of high cyclist expectation and rigorous industry standards (e.g., ISO 4210, EN 15194).

Key Specifications Table

| Parameter | Value/Range |

|---|---|

| Motor Type | Brushless Geared Hub Motor |

| Rated Power (W) | 250W - 750W |

| Peak Torque (Nm) | 45Nm - 70Nm |

| Voltage Compatibility | 36V / 48V DC |

| O.L.D. Standard | 135mm or 142mm |

| Cassette Compatibility | 8/9/10/11-speed standard |

| Brake Interface | ISO 6-Bolt Disc Brake |

| Efficiency Rating | 85% |

Primary Applications

-

High-End Commuter Bikes: Requiring multi-speed compatibility for varied urban terrain and distances.

-

E-Touring and Trekking Bikes: Delivering balanced power and range for long-distance travel with luggage.

-

Premium Folding E-Bikes: Where a strong, integrated rear drive unit is needed without compromising the fold mechanism.

Key Competitive Advantages

-

Wide Cassette Compatibility: Supports up to 11-speed cassettes, giving bicycle brands flexibility in drivetrain choice.

-

Optimized Torque Delivery: Higher pole count and advanced winding for excellent climbing power at commuter speeds.

-

Low Motor Drag: Premium clutch mechanism ensures seamless freewheeling when not using power, enhancing battery life.

-

Superior Component Life: Reinforced freehub shell and high-grade bearings ensure longevity even under high-cadence shifting stress.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China Rear Cassette Hub Motors Manufacturers and China Rear Cassette Hub Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体