| Power | Stall Torque | Weight(KG) |

| 350-750 | 85 | 5.3 |

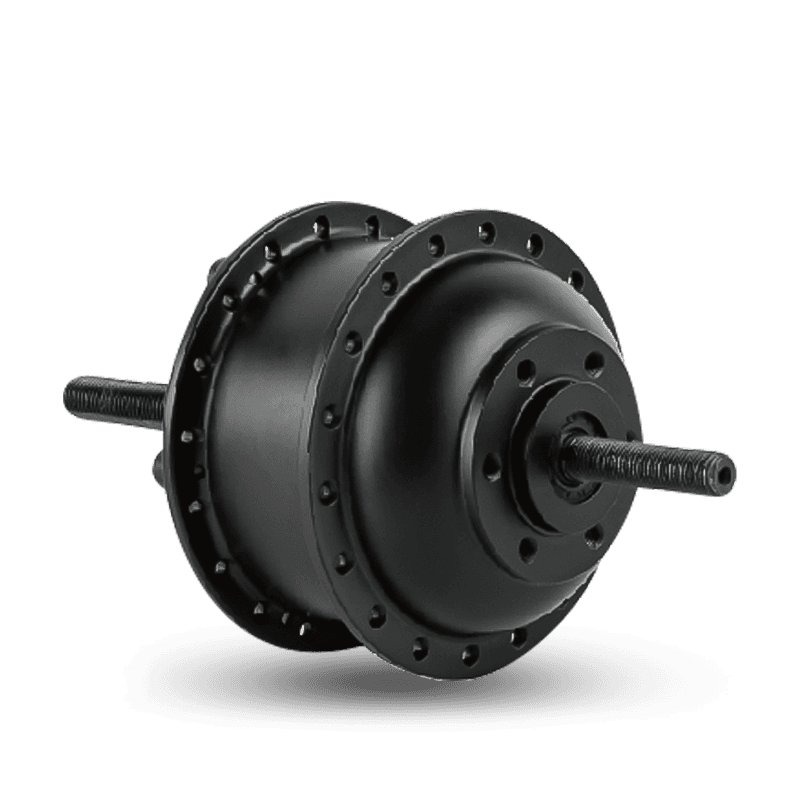

750W Fat Tire Bike Motors

-- Steady & Reliable Manufacturer --

Conquering All Terrains: The Power of 750W Fat Tire Propulsion

The rise of the fat tire e-bike has redefined what is possible in off-road mobility, and at the heart of this revolution is the 750W fat tire bike motor. As a manufacturer with over 30 years of electromechanical innovation, we have witnessed the shift from standard commuter bikes to these high-torque beasts designed for sand, snow, and rugged trails. Our facility, formerly known as "Hengtai Motor," has spent decades refining the specialized architecture required to drive wider rims and heavier tires. In a fat tire configuration, the motor faces unique challenges: increased rolling resistance and the need for a much wider dropout (typically 170mm to 190mm). We have met these challenges by utilizing our 500-ton die-casting machines to create reinforced aluminum-magnesium alloy housings that provide the structural integrity needed to handle extreme lateral forces while maintaining superior thermal dissipation.

Precision manufacturing is the cornerstone of our 750W series. Within our 9,000-square-meter campus, we implement a rigorous ISO 9001 quality control system that governs everything from the initial casting to the final micro-arc oxidation coating. This coating is particularly vital for fat tire bikes, which are often ridden in corrosive environments like coastal beaches or salted winter roads. The 750W power tier is the "sweet spot" for North American markets, providing the maximum legal power allowed in many jurisdictions while delivering the 80Nm to 85Nm of torque required to climb steep inclines without overheating. Our engineering team utilizes high-grade silicon steel laminations and oxygen-free copper windings to ensure that electromagnetic efficiency remains above 82%, even under heavy load. This efficiency is what allows riders to explore further into the wilderness without the fear of premature battery depletion.

Historically, our commitment to durability was solidified through a landmark testing program where our motors were subjected to a 30,000-mile endurance run. We were proud to see over 50 of our units exceed the 50,000-mile mark without mechanical failure. For a 750W fat tire motor, this longevity is achieved through our Patented Nylon-Steel Gear technology. By using a hybrid gear set, we provide the silence and shock absorption of nylon with the sheer mechanical strength of steel. This prevents the "stripped gear" syndrome that often plagues high-torque motors when they encounter sudden resistance. When you choose our 750W solution, you are not just buying a motor; you are investing in three decades of manufacturing excellence and a proven track record of all-terrain performance.

High-Torque Performance Specifications

| Technical Parameter | Metric Value | Technical Notes |

|---|---|---|

| Rated Continuous Power | 750W (Peak 1200W) | Optimized for US Class 2/3 |

| Maximum Torque | 80Nm - 90Nm | High-reduction planetary system |

| Dropout Width | 170mm / 175mm / 190mm | Compatible with 4.0 - 5.0 inch tires |

| Nominal Voltage | 48V / 52V DC | High-voltage efficiency curve |

| Gear Reduction Ratio | 1:5.3 | Maximum low-end grunt |

| Magnet Material | 38H Neodymium | 120°C high-temp resistance |

| Efficiency Peak | ≥ 83% | Low energy loss at cruise |

| Noise Level | < 52dB | Silent hybrid gear technology |

| Protection Rating | IP65 / IPX6 | Double-lip axle seals |

| Surface Treatment | Micro-arc Oxidation | Anti-corrosion for coastal use |

Dominating Off-Road and Utility Applications

The primary application for our 750W drive units is the All-Terrain Adventure Fat Bike. These vehicles are designed for enthusiasts who demand the ability to ride through soft sand, deep mud, and fresh snow where a standard tire would sink. The 750W output provides the necessary momentum to keep these oversized tires spinning. Additionally, these motors are increasingly being used in Electric Hunting Bikes. In this context, the silence of our patented gears allows hunters to navigate quietly through the woods while the 85Nm of torque enables them to haul heavy gear or game back out of the wilderness with ease.

- Electric Snow-Bikes for winter resort transportation and recreation.

- Beach Cruisers designed for soft-sand coastline exploration.

- Heavy-Duty Utility Cargo Bikes for rural delivery routes.

- Off-Road Rental Fleets in rugged park environments.

- Ruggedized Commuter Bikes for cities with poor road infrastructure.

The HENTACH Manufacturing Advantage

The core advantage of our 750W motor lies in its Thermal Management System. High-wattage hub motors generate significant heat, especially when driving heavy fat tires uphill. Our use of 500-ton die-casting for the housing ensures a dense, high-conductivity aluminum-magnesium structure that pulls heat away from the internal windings. This is further enhanced by our internal "stator-cooling" geometry, which maximizes airflow during rotation. For B2B partners, this means a significantly lower rate of thermal shutdown and motor "burn-out" compared to cheaper alternatives that use stamped steel covers.

Furthermore, our 30-Year Electromechanical Legacy ensures that we have addressed the common failure points of hub motors. Our axle design uses 40Cr reinforced steel with precision CNC-machined flats to prevent axle spin-out—a common issue in high-torque fat tire frames. By controlling every step of the manufacturing process from casting to the final QC bench, we provide a motor that has been proven to last over 50,000 miles. This reliability is backed by an ISO 9001 certified facility, giving our global clients the peace of mind that their brand's reputation is built on a solid foundation of engineering excellence.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

As China 750W Fat Tire Bike Motors Manufacturers and China 750W Fat Tire Bike Motors Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

English

English 中文简体

中文简体