Don't hesitate to send a message

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

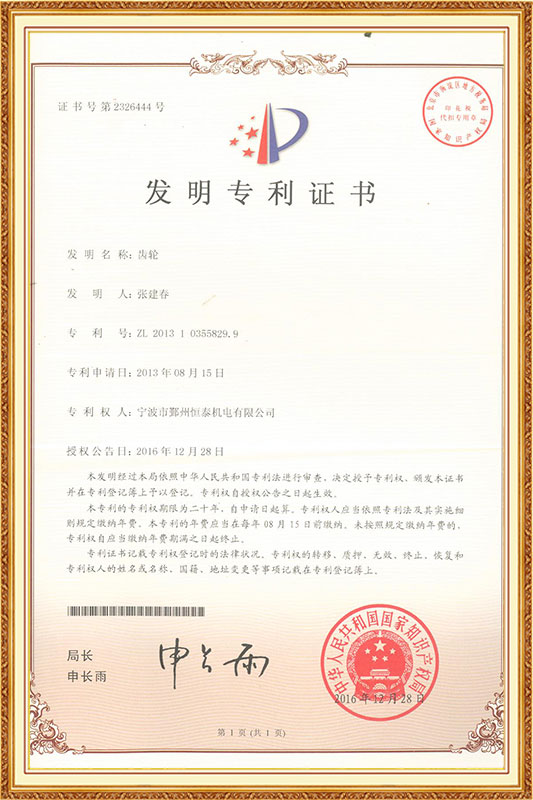

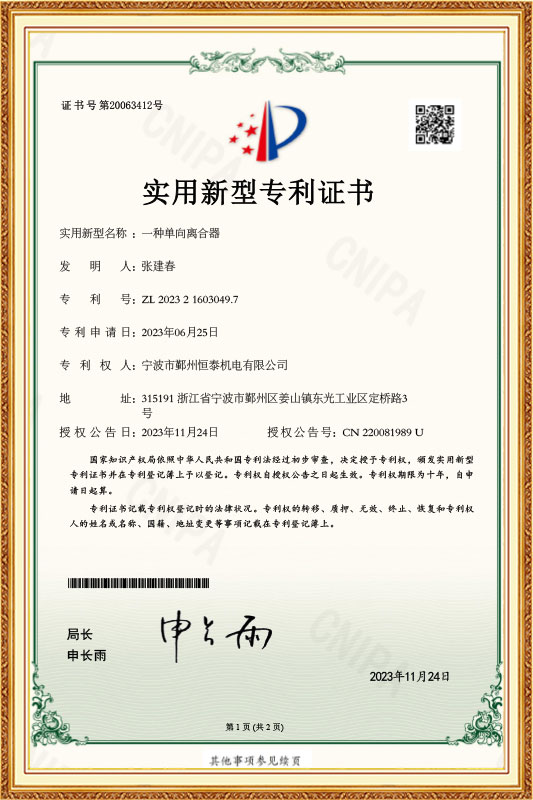

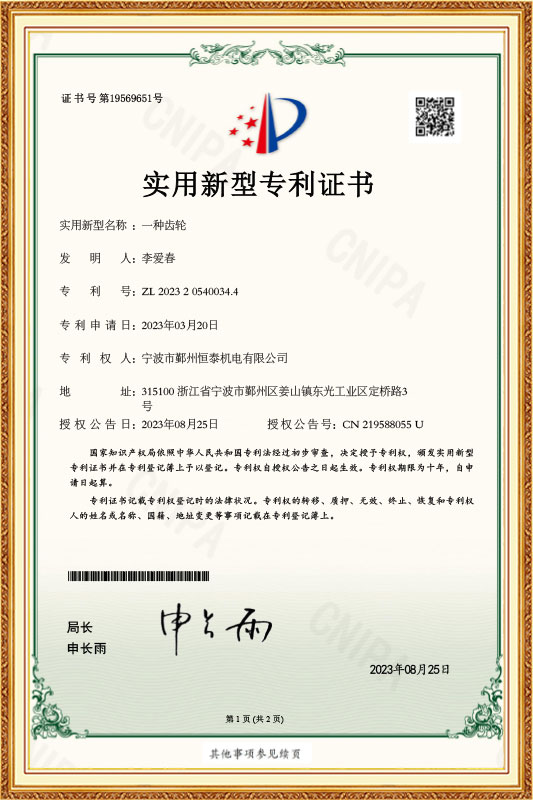

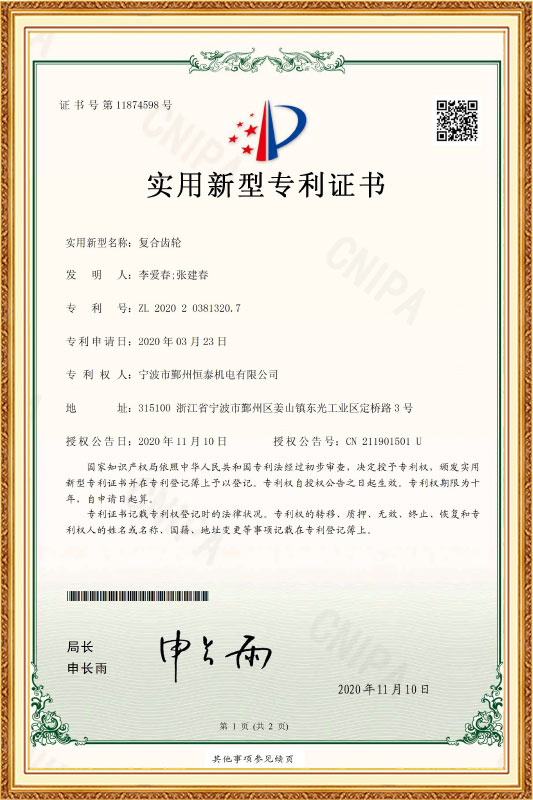

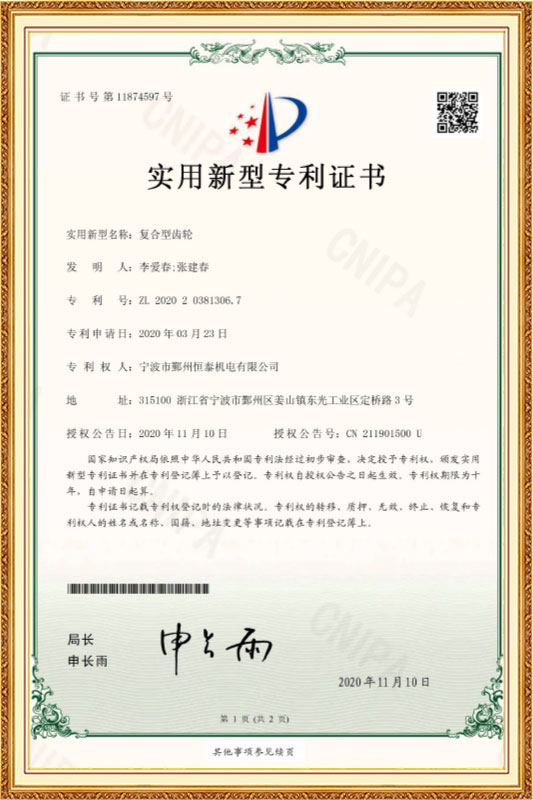

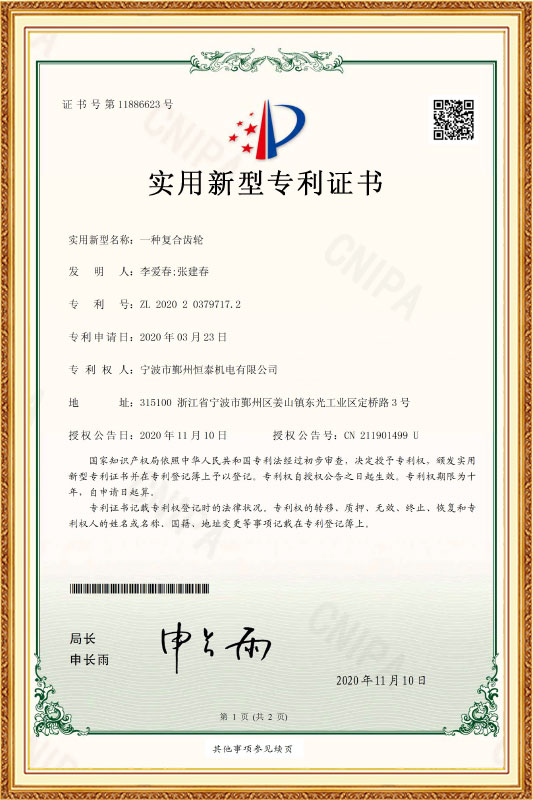

As China Miniature DC Motors Manufacturers and Electric Vehicle Hub Motor Factory, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

Miniature DC Motors: Compact Power for Smart Mobility and Beyond

Miniature DC motors are small DC drive motors used in a wide range of applications requiring compact size, low voltage, high efficiency, and precise control. Their light weight and high torque-to-weight ratio allow them to be used in a wide range of applications, including e-bikes and light mobility systems, medical devices and instruments, consumer electronics, robotics, and automation.

Engineers are increasingly integrating brushless DC motors for greater energy efficiency, lower heat generation, and more precise feedback control. Miniature motors are now being custom designed for specific products, whether it’s waterproofing for outdoor scooters or gear motor integration for high-torque tasks. HENTACH’s nylon-steel composite gears significantly improve durability and reduce wear, with performance 5 times higher than traditional nylon gears.

HENTACH uses advanced CNC and die-casting manufacturing processes to ensure precision and consistency in Miniature DC motor manufacturing, as well as high-quality stator windings and gear integration to ensure long life and quiet operation. The motors produced by HENTACH have a reliable operating record of more than 50,000 kilometers in actual use scenarios, and have passed the ISO9001 certification system to ensure strict quality control.

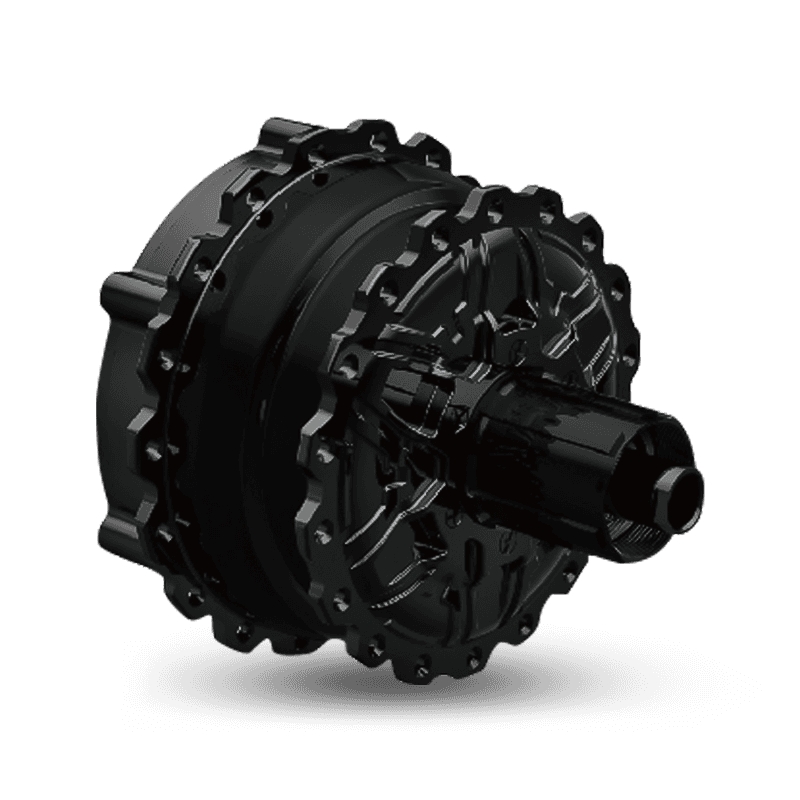

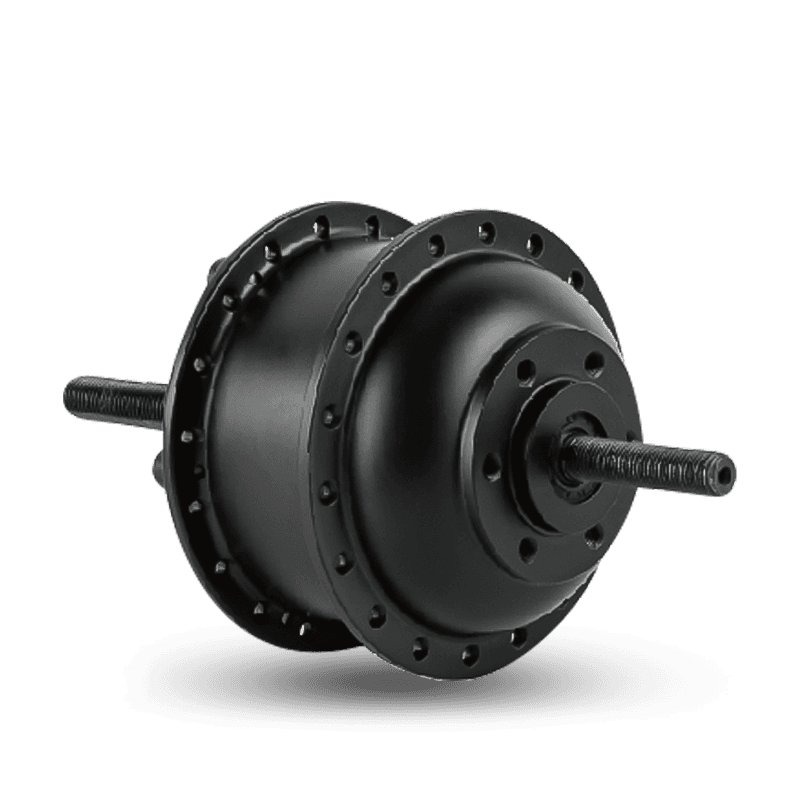

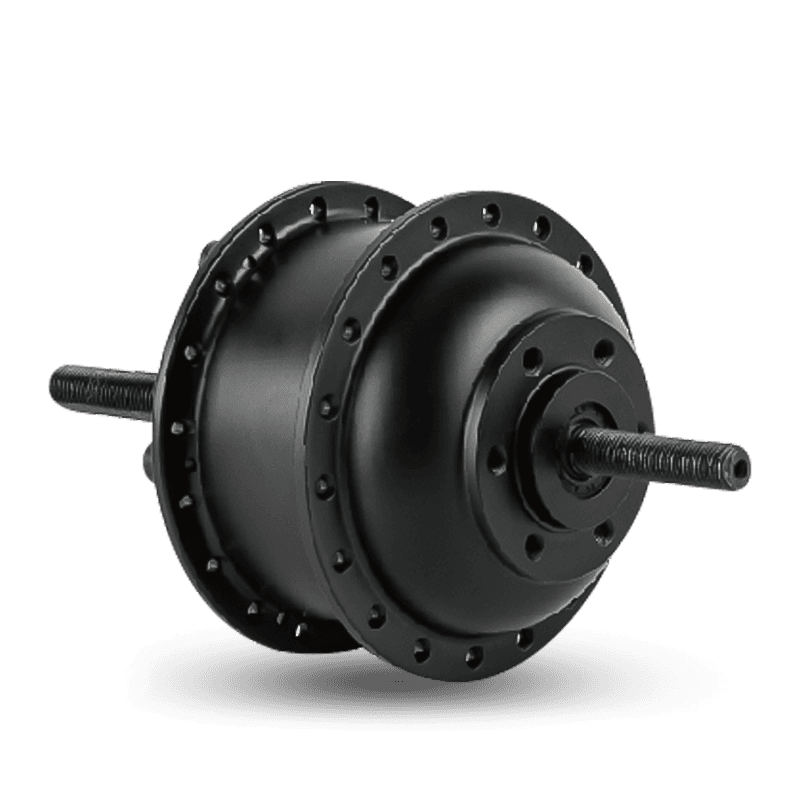

The electric vehicle hub motor is a direct-drive motor integrated into the vehicle's wheel hub. Unlike traditional electric drive systems, the hub motor eliminates the chain, belt and gearbox and converts electrical energy directly into wheel rotation. Hub motors have become the first choice for electric bicycles and electric mountain bikes, electric cargo bikes and delivery scooters, electric tricycles and mopeds, and electric fat tire bikes and off-road vehicles.

The HENTACH hub motor is equipped with a patented nylon steel gear, which has a torque resistance of 5 times that of standard nylon gears. It is very suitable for applications with torque greater than 100Nm, and the rear chainstay size can be customized. It is compatible with various models from 100mm to 190mm, with a peak torque of up to 170Nm, which can easily climb hills, adopts a heavy-duty traction and sealed efficient design, low maintenance cost and durability, suitable for long-distance use.

HENTACH has produced E-Type F500, E-Type RC750 Pro, S-Type F750 and other power from 250 to 750 for various scenarios.

Electric vehicle hub motors continue to develop, with integrated controllers, sensors and CAN bus support, so as to achieve intelligent drive systems and IoT connectivity. As shared electric bicycle and scooter systems develop globally, motors must be able to withstand high usage, minimum maintenance cycles and diverse environments. HENTACH uses aluminum-magnesium alloy and gear composite materials to comply with the global trend of energy conservation and emission reduction, which is critical to vehicle range and performance.

Founded in 1995, HENTACH has more than 20 years of experience in the motor and casting industry, with a 9,000 square meter factory equipped with more than 60 advanced production and testing equipment, from die casting to motor assembly and testing, with independent production capabilities. Products are distributed all over the world, with mature products in Europe, Asia and North America.

Miniature DC motors and electric vehicle hub motors are at the core of future urban transportation and intelligent mechanical systems. HENTACH's deep technical expertise, patented gear solutions, and full-cycle production capabilities make it a strategic supplier and innovation partner in this rapidly growing field.

Whether it's OEM integration or new electric vehicle development, HENTACH is ready to power the next generation of mobility.

English

English 中文简体

中文简体