Don't hesitate to send a message

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. was established in 1995. For more than 20 years, we have been committed to the casting and processing of miniature DC motors, hub motors for electric vehicles and motorcycles, and aluminum and magnesium alloys for electric vehicles. At the same time, we have a complete ISO9001 quality control system, mature management system and advanced manufacturing and testing equipment.

HENTACH has an area of more than 9,000 square meters, with a construction area of 5,000 square meters. Currently we have more than 60 sets of various internal production equipment including 500 tons die-casting machines, precision CNC machine tools, laser marking machines, micro-arc oxidation, etc., and another two sets of electric vehicle motor test benches.

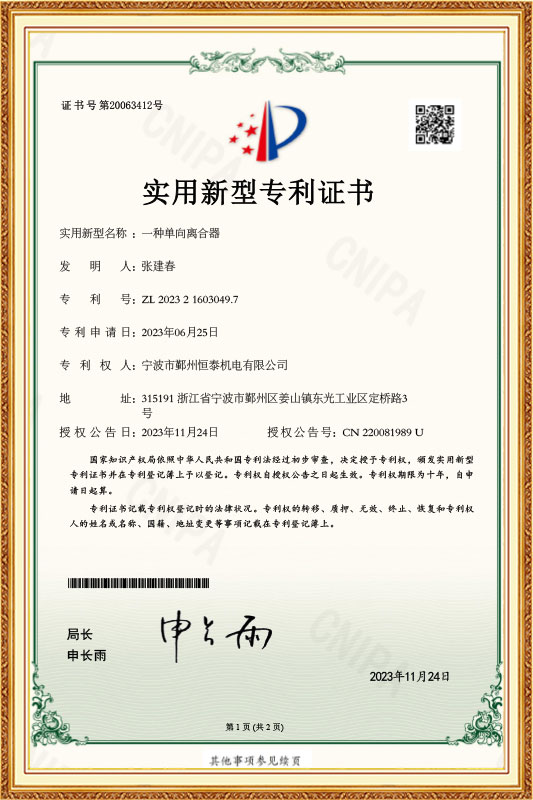

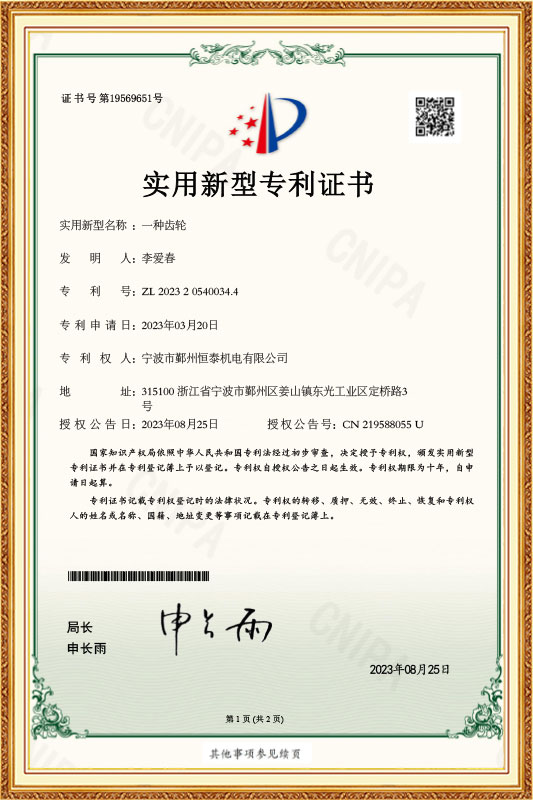

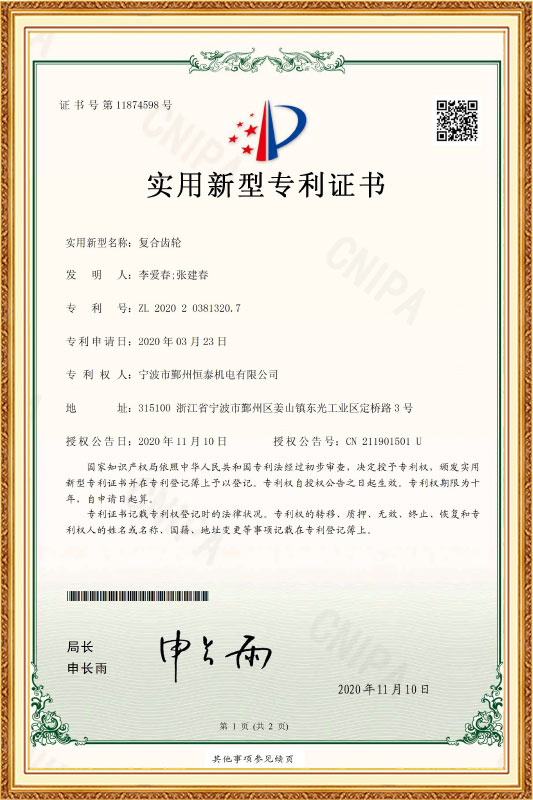

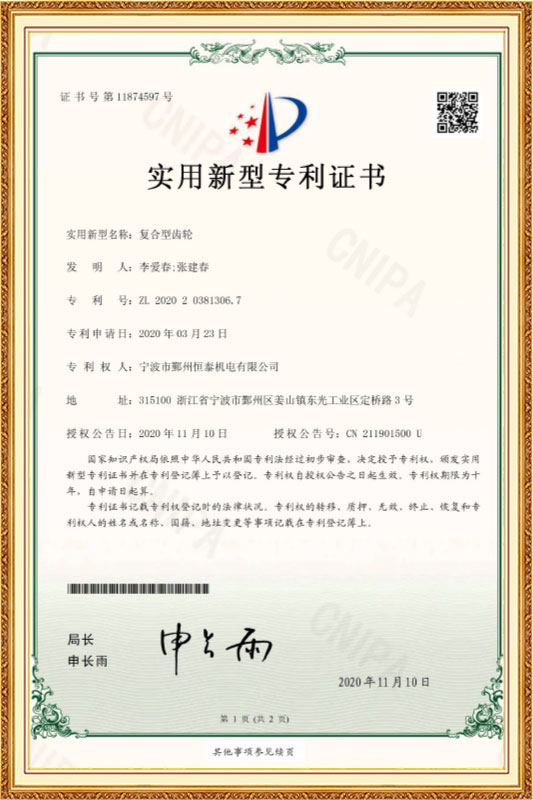

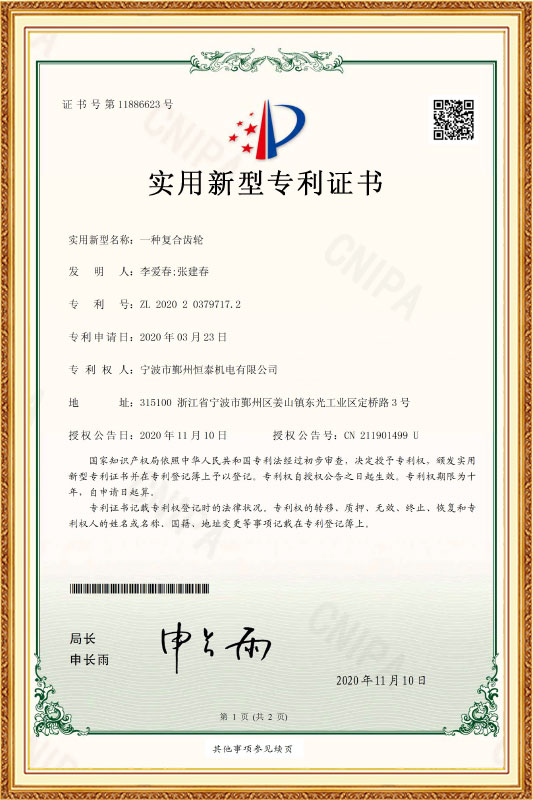

As China E-City Bike Motor Manufacturers and E-City Bike Motor Suppliers, HENTACH aims to pursue higher quality and innovation products. With rich experience in motor manufacturing, we are confident with our motor quality as we always use the materials and our own patented nylon-steel gear. We used to set up a price for the customers who use our motors for over 30,000 miles. In the end we find over 50 motors that are used by the customers for over 30,000 miles and some of them even reach 50,000 miles. We appreciate for those customers who are always trust our products, which also encourage us to keep exploring and innovating better motor with quality.

E-City Bike Hub Motor: The core driver of the development of urban electric-assisted bicycles

As the core power system for urban green travel, E-City Bike Hub Motor is experiencing rapid development. The demand for urban electric-assisted bicycles is growing, and hub motors have become the mainstream choice with their compact structure, easy installation, and low maintenance costs. Especially in typical urban scenarios such as high-frequency start-stop, congested roads, and light-load climbing, the high-efficiency output and low-noise operation of the motor are particularly critical. The current industry development trend is evolving towards lightweight, high power density, and intelligence. Intelligent hub motors with torque sensors and communication control systems are gradually becoming the preferred configuration for vehicle brands.

The urban riding environment has the characteristics of frequent start-stop, lightweight requirements, quietness and comfort, as well as protection and durability. When riding on roads with dense traffic lights and many intersections, the motor starting response and low-speed torque requirements are high. Most riders pay more attention to the weight of the vehicle, requiring the motor to be compact and light, and urban residents are more sensitive to motor noise and vibration. These factors determine that the motor must have multiple performance advantages such as fast response, compact structure, durability and reliability, and low noise.

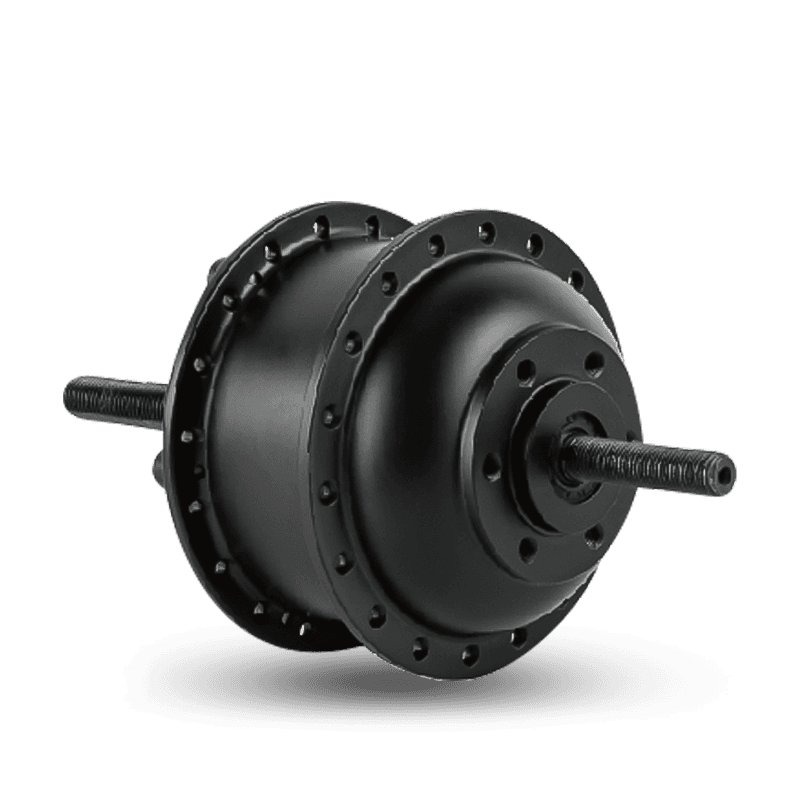

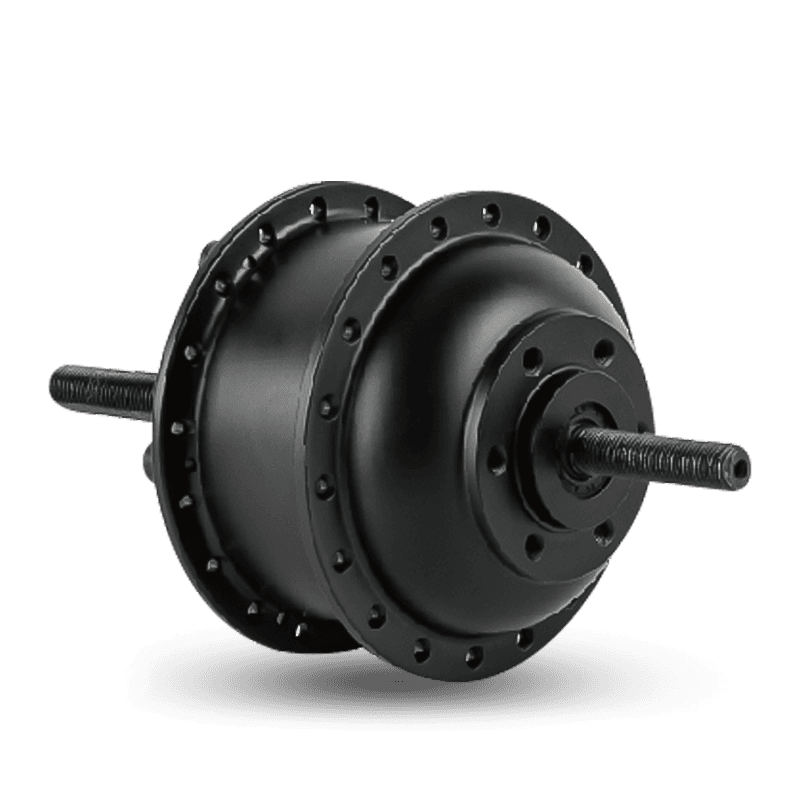

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd.'s many E-City motors use an outer rotor structure, which has the following technical advantages over inner rotor motors: higher torque output, suitable for frequent starting and stopping and small slopes in the city; more stable structure, reduced cumulative errors, and longer service life; more suitable for small-volume motors, which helps to lighten the vehicle and optimize space. Ningbo Yinzhou HENTACH Electromechanical Co., Ltd.'s HT MINI series E-City Bike Hub Motor outer rotor motor weighs only 1.95kg, but can output up to 40Nm peak torque, achieving a perfect balance between lightness and performance. Ningbo Yinzhou HENTACH Electromechanical Co., Ltd.'s core motors are all equipped with self-developed plastic-steel composite teeth, which are 5 times stronger than traditional nylon gears and can achieve a continuous service life of more than 30,000 kilometers. Some customers have measured more than 50,000 kilometers. It has low noise and strong wear resistance, which is particularly suitable for frequent start-stop conditions of urban electric assist. This gear system is an important quality advantage that distinguishes Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. from similar brands. All Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. E-City series motors support IP65 waterproof and dustproof, which can easily cope with rainy and snowy climates, dusty environments and slippery areas on urban roads, ensuring stable operation of the vehicle and reducing after-sales maintenance.

Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. provides vehicle manufacturers with a variety of E-Bike motor adaptation solutions, fully meeting different models, usage scenarios and user preferences, demonstrating its high customization and system integration capabilities. First of all, in terms of transmission system matching, Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. supports two solutions: 7-speed gearshift and 8-10-speed card-fly. The gearshift has a simple structure and low cost, which is suitable for entry-level or urban commuter models; while the card-fly system has better shifting accuracy and durability, and is suitable for mid-to-high-end city cars, mountain bikes, etc., to meet users' higher requirements for speed change performance under complex road conditions. Secondly, Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. provides two drive modes: front-wheel drive and rear-wheel drive. The front-drive motor has a simpler structure and is suitable for light commuter vehicles, with good traction and strong steering stability; the rear-drive motor can directly apply power to the drive wheels, bringing higher traction efficiency and climbing ability, and is suitable for vehicles with higher torque requirements such as freight vehicles and electric fat tire vehicles. Through flexible interface solutions and rich selection combinations, Ningbo Yinzhou HENTACH Electromechanical Co., Ltd. not only provides complete wheel hub motor system support for vehicle manufacturers, but also makes its products more market-adaptable and differentiated.

English

English 中文简体

中文简体